Drilling resumes at Renforth Resources’ Surimeau battery metals project in Quebec – Richard Mills

2023.11.08

The latest edition of the IEA’s Critical Minerals Market Review reveals that supply sources of key EV metals like nickel and cobalt remain heavily concentrated (in Indonesia and the DRC, respectively), despite efforts to rectify that.

A key takeaway from the report is that the West still has a long way to go before having a reliable, sustainable supply of critical minerals, and more mining projects must be developed domestically

A potential hot spot is Quebec, and Renforth Resources (CSE:RFR, OTCQB:RFHRF, FSE:9RR) stands to benefit from continued exploration of its Surimeau property.

Outokumpu model

Mineralization at Surimeau consists primarily of disseminated sulfides, hosted in carbonatized, albitized and silicified rocks at the sheared contacts between serpentinite and graphitic mudstones, and within the mudstones themselves, consisting of varying levels of nickel, copper, cobalt, zinc and anomalous platinum group elements (PGEs).

Surimeau’s geology is best described as a sulfide nickel magmatic sulfide deposit, juxtaposed with a copper-zinc massive sulfide deposit. The nickel-containing ultramafic orebody has been fused with the VMS deposit alongside it, giving it a unique geological flavor.

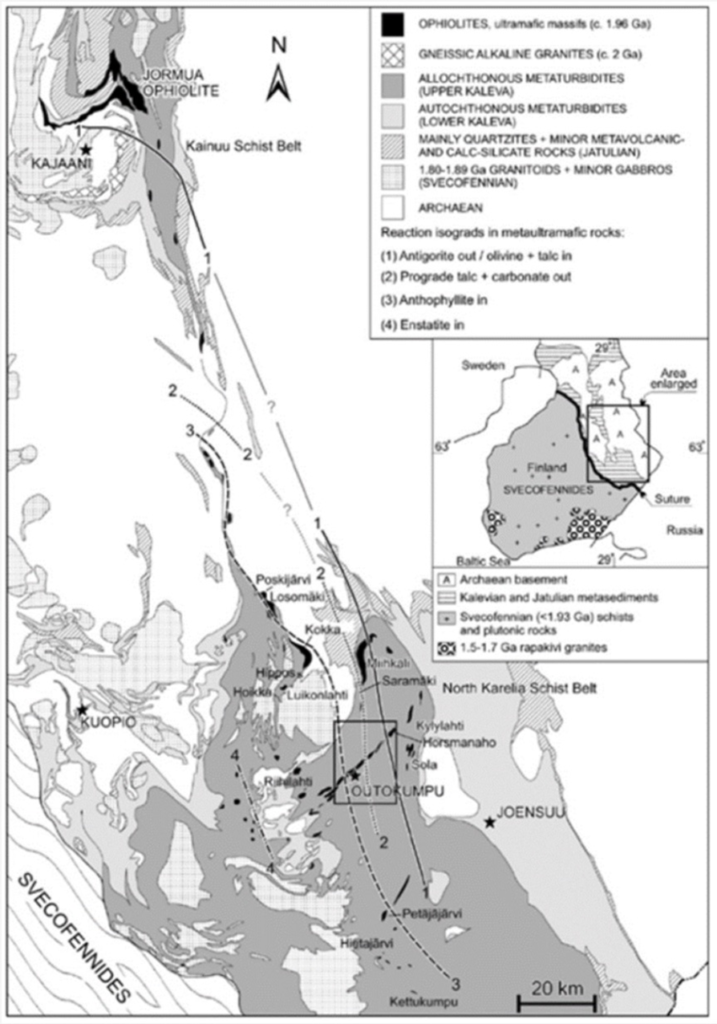

This style of mineralization is rare; however, it is known to occur in the Outokumpu District of Finland, which contains sulfide deposits with economic grades of copper, zinc, cobalt, nickel, silver and gold.

These deposits are formed by structural juxtaposition of two types of mineralization — magmatic nickel-copper-platinum group metals, and stratabound syngenetic zinc-copper VMS types. Additionally, in the Outokumpu mines, black graphitic schist hosts the deposits.

Mining from 1913 to 1988 exploited three major deposits — Outokumpu, Vuonos and Luikonlahti — with total production of around 50 million tonnes of ore containing 2.8% copper, 1% zinc, 0.2% cobalt, and minor amounts of nickel and gold.

The Outokumpu analog was first proposed by Dr. James Franklin. CEO Nicole Brewster brought him on as a technical advisor in 2021. Franklin is a member of the Canadian Mining Hall of Fame, and the former chief scientist for the Geological Survey of Canada.

Dr. Franklin agreed to look at Surimeau in part due to his expertise in VMS mineralization; he “wrote the book” on several exploration techniques for vectoring towards a “black smoker” VMS, which is a blind structure. The mineralization and setting Renforth is seeing at Victoria, in the center of Surimeau, might suggest a “feeder system” for a VMS, which Dr. Franklin has confirmed indication of, in his geochemical analysis of Renforth’s assay results.

The “Outokumpu model”, as designated by Renforth’s technical team, is based on the company’s initial 2020 drilling which intersected significant mineralized graphitic mudstone in two of the three holes, as well as its follow-up 2021 drilling. The results of the most recent drilling also support this model.

Renforth interprets the Victoria mineralized horizon, which stretches ~20 km west to east across the central portion of the ~330 square km Surimeau property, to be an “Outokumpu-style” mineralized occurrence, commencing on surface to the deepest pierce point drilled to date, ~160m vertical depth.

The Outokumpu-type assemblage found at Surimeau generally consists of carbonate rock, calc-silicates and serpentinite in close contact with bands of graphitic mudstones that are generally less than 5 meters thick. Structural repetition is evident in drill core where in certain cases there are multiple repeated sequences.

Bioleaching

Bioleaching refers to the extraction of metal from sulfide ores or concentrates using materials found in the environment.

In nature, bioleaching is triggered spontaneously by microorganisms in the presence of air and water. Commercial bioleaching technologies use the same phenomenon but accelerate this natural process.

Microorganisms catalyze the oxidation of iron sulfides to create ferric sulfate and sulfuric acid. Ferric sulfate, a powerful oxidizing agent, then oxidizes the copper sulfide minerals, and the contained copper is then leached by the sulfuric acid.

The world’s first bioheapleach project for nickel, and other battery metals, occurs just north of the Outokumpu District, at the Talvivarra mine, hosting mineralization containing nickel, copper, zinc and cobalt.

The heap-leach mine extracts ore from two small open pits, producing nickel and cobalt sulfates for batteries. Operator Terrafame states:

“The main factor behind the small carbon footprint is our bioleaching method, which consumes considerably less energy than conventional methods. The ore does not need to be crushed nor grinded as fine as in the traditional process, and high-temperature metallurgical processes are not used in further processing.”

At Talvivaara the bacteria used in the bioleaching process grow naturally in the ore. The company reports recovery rates of up to 98% of metal from ore to solution.

The heap leaching operates in two stages: a primary heap pad residence time of 1.5 years, and a secondary pad residence time of 3.5 years.

The process plant design includes two parallel circuits each rated at 600m3/h of pregnant leach solution (PLS). Each circuit consists of copper recovery, zinc recovery, neutralisation and aluminium removal, nickel and cobalt recovery, iron removal and then final precipitation.

The copper and zinc recovery units precipitate the metals from their sulphides in the PLS using hydrogen sulphide. The precipitates are then recovered in thickeners and filtered to produce saleable products. (Mining Technology, Nov. 16, 2008)

The potential for using bioleaching to process the ore at Surimeau is behind Renforth’s latest news announcing the appointment of its second technical advisor.

Dr. Nadia Mykytczuk’s focus will be on “the research and development of responsible and sustainable technology and practices for the processing of mineralized material at Surimeau in the future,” states the Oct. 4 press release. Mykytczuk, who won the Innovation Award at the 2022 Northern Ontario Business Awards, is president and CEO of Sudbury’s Mining Innovation Rehabilitation and Applied Research Corp. (MIRARCO), a non-profit research arm of Laurentian University; and the executive director of the university’s Goodman School of Mines.

Renforth’s CEO Brewster says, “Dr. Mykytczuk’s expertise is in the use of biological agents to remove elements from the environment, the biggest use of this in Northern Ontario is in the remediation of old mine sites which have left deleterious elements behind causing pollution. I was introduced to Nadia through a mutual professional acquaintance, we could both see a synergy between Renforth’s Surimeau and Nadia’s work in bleaching, along with the Centre she is building that will give her the ability to test material from Surimeau to determine if we can process using bioheapleaching, as is done at Talvivaara for their low grade nickel polymetallic.”

Brewster continues, “As a well-regarded academic Dr. Mykytczuk has already signed agreements, formed relationships, and visited Finland in order to take the initial steps to advance our mutual agenda of testing Surimeau material. In addition, Dr. Mykytczuk gives us additional access to the academic world as she is actively publishing and working within the grant/research/R&D funding world as she uses that ecosystem to advance the not-for-profit MIRARCO she runs with Laurentian university.

Because this work can take time, Renforth management says it “has determined it is prudent to start R&D now, while it continues to advance the central portion of the Victoria mineralized structure at Surimeau geologically,” and “with the intent that the R&D timeline, and the geological timeline, will converge at some point in the future.”

In a note to shareholders, Brewster said Mykytczuk’s expertise will potentially help Renforth avoid building a crushing circuit that feeds a waste-generating smelter, that would have to be safeguarded and managed.

Brewster compared bioleaching at the Talvivaara mine to RFR’s own research and development of the technology, to be led by Mykytczuk.

“If our R&D works, then we are doing something no one else is here, in Quebec, employing new technology in a new deposit style to produce battery chemistry….without building a smelter. That is an end worth working towards,” she wrote.

Exploration focus

For the past two years, Renforth’s exploration focus has been on the more advanced Victoria mineralized battery metals horizon and parts of the longer Lalonde horizon lying parallel to the north.

Victoria is a ~20-km-long magnetic structure bearing nickel, copper, zinc and cobalt mineralization at surface. It stretches between the Victoria West mineralization, the central area which has been drilled over 2.2 km, and the Colonie mineralization, historically drilled and surface-sampled by Renforth in the eastern part of the property.

The Lalonde mineralization, ~3 km north of Victoria West, was only recently drilled by Renforth. This surface mineralized system, similar to Victoria, currently stretches over ~9 km of ground-truthed strike.

Both zones are about 250-500 meters thick, running east-west across the central portion of the property. The two systems are interpreted by the company as two arms of a fold, with the fold nose located off the property and to the east.

While the defined area of mineralization spans a total length of ~29 km, which by industry standards is a long distance to cover, this is a small portion of a district-scale property that remains underexplored.

Earlier this year, the Renforth team started to move farther out, drilling in an area about 4 km west of the Victoria structure where work first began on the property.

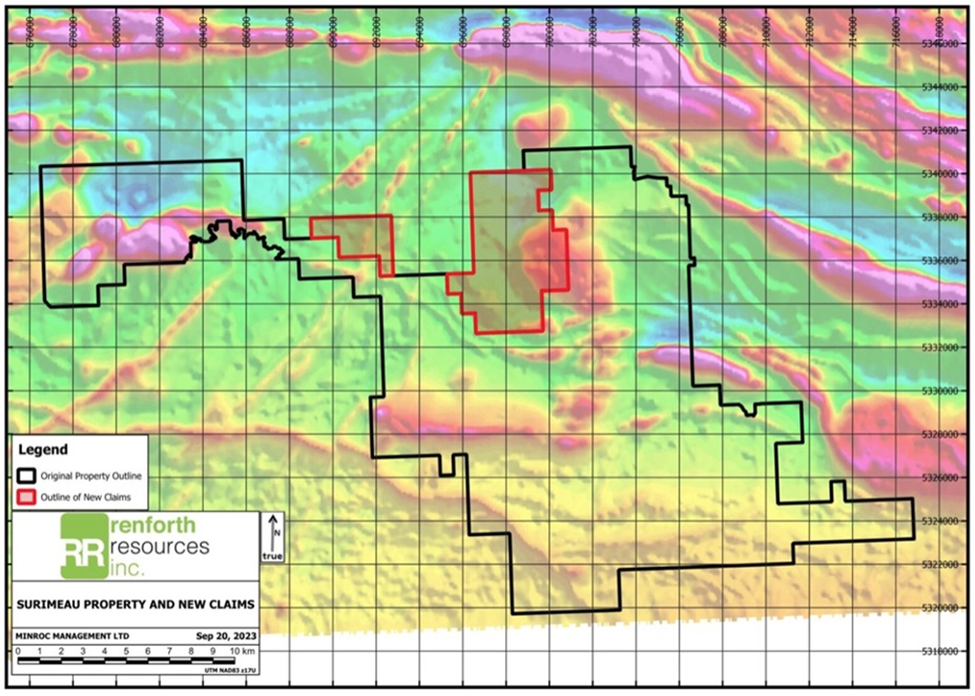

In September, Renforth staked an additional 62 claims north of Lalonde — the balance of the mineralized magnetic anomaly discovered in the latest prospecting program — as well as historical government soil samples.

An airborne electromagnetic/magnetic survey interpreted the western end of Victoria as showing an interesting curvature, possibly representing folding which may have resulted in mineralized fluid entrapment.

As far as we know, the ~20 km Victoria trend consists of ultramafic flows intercalated with graphitic mudstones, albite shears and calc-silicate rocks. The ultramafics and calc-silicates are what host most of the higher-grade nickel and cobalt mineralization, while the graphitic mudstones and albite shears host most of the higher-grade zinc and copper mineralization as sphalerite and chalcopyrite, respectively.

Surface sampling identified mineralization within the ultramafic rocks, with bands of calc-silicates typical of the Victoria system. Except for Renforth’s prospecting, the western end of Victoria had not been previously explored or drilled.

Fall drill program

The next stage of field work at Victoria involves an in-fill drill program along the 2.2 km of strike, which hosts historical pits, Renforth’s stripping, and prior drill programs concerning the surface nickel, cobalt, copper, zinc, silver and gold mineralization. The program will focus on the central part of the structure.

According to Renforth, a series of drill holes approximating 4,000 meters are designed to undercut previous mineralization, to infill the spacing along strike to about 100m between drill holes. The drilling is being done to support a maiden NI 43-101 mineral resource estimate, and to collar additional holes in the north (drilled south as the mineralization dips north) to intersect the three mineralized repetitions identified to date.

Beaupré copper discovery

In the Nov. 7 news release, Renforth also said it has completed stripping at the Beaupré showing in the northeastern part of the property, to expand on where prospecting and minor trenching in 2019 returned copper values of up to 3.59%. Sulfides are visible on surface.

Pegmatite targets

Finally, the company has completed follow-up prospecting on several pegmatite targets prospective for spodumene, a commercially important source of lithium. Samples were submitted for assay.

Beginning in 2022, Renforth started paying more attention to the potential presence of lithium, separate from Victoria and Lalonde, through the sampling of pegmatites and anomaly clusters.

Pegmatites, which are coarse-grained intrusive igneous rocks formed from crystallized magma below the Earth’s crust, can contain extractable amounts of lithium, most commonly found in the mineral spodumene. This is why pegmatite lithium deposits are also known as hard-rock lithium.

Renforth Resources

CSE:RFR, OTCQB:RFHRF, FSE:9RR

Cdn$0.025; 2023.11.07

Shares Outstanding 325m

Market cap Cdn$8.1m

RFR website

Richard (Rick) Mills

aheadoftheherd.com

subscribe to my free newsletter

Legal Notice / Disclaimer

Ahead of the Herd newsletter, aheadoftheherd.com, hereafter known as AOTH.

Please read the entire Disclaimer carefully before you use this website or read the newsletter. If you do not agree to all the AOTH/Richard Mills Disclaimer, do not access/read this website/newsletter/article, or any of its pages. By reading/using this AOTH/Richard Mills website/newsletter/article, and whether you actually read this Disclaimer, you are deemed to have accepted it.

Any AOTH/Richard Mills document is not, and should not be, construed as an offer to sell or the solicitation of an offer to purchase or subscribe for any investment.

AOTH/Richard Mills has based this document on information obtained from sources he believes to be reliable, but which has not been independently verified.

AOTH/Richard Mills makes no guarantee, representation or warranty and accepts no responsibility or liability as to its accuracy or completeness.

Expressions of opinion are those of AOTH/Richard Mills only and are subject to change without notice.

AOTH/Richard Mills assumes no warranty, liability or guarantee for the current relevance, correctness or completeness of any information provided within this Report and will not be held liable for the consequence of reliance upon any opinion or statement contained herein or any omission.

Furthermore, AOTH/Richard Mills assumes no liability for any direct or indirect loss or damage for lost profit, which you may incur as a result of the use and existence of the information provided within this AOTH/Richard Mills Report.

You agree that by reading AOTH/Richard Mills articles, you are acting at your OWN RISK. In no event should AOTH/Richard Mills liable for any direct or indirect trading losses caused by any information contained in AOTH/Richard Mills articles. Information in AOTH/Richard Mills articles is not an offer to sell or a solicitation of an offer to buy any security. AOTH/Richard Mills is not suggesting the transacting of any financial instruments.

Our publications are not a recommendation to buy or sell a security – no information posted on this site is to be considered investment advice or a recommendation to do anything involving finance or money aside from performing your own due diligence and consulting with your personal registered broker/financial advisor.

AOTH/Richard Mills recommends that before investing in any securities, you consult with a professional financial planner or advisor, and that you should conduct a complete and independent investigation before investing in any security after prudent consideration of all pertinent risks. Ahead of the Herd is not a registered broker, dealer, analyst, or advisor. We hold no investment licenses and may not sell, offer to sell, or offer to buy any security.

Richard does not own shares of Renforth Resources (CSE:RFR). RFR is a paid advertiser on his site aheadoftheherd.com

This article is issued on behalf of RFR

Legal Notice / Disclaimer

Ahead of the Herd newsletter, aheadoftheherd.com, hereafter known as AOTH.Please read the entire Disclaimer carefully before you use this website or read the newsletter. If you do not agree to all the AOTH/Richard Mills Disclaimer, do not access/read this website/newsletter/article, or any of its pages. By reading/using this AOTH/Richard Mills website/newsletter/article, and whether you actually read this Disclaimer, you are deemed to have accepted it.