Top 5 Uses of Copper

2022.04.08

As the oldest metal known to man, copper has been an essential material that helped to shape and transform many civilizations, from the ancient Egyptians, Romans to modern day cultures.

One may even go as far as to say society could not have survived without copper. This is because the metal has many useful properties (high ductility, malleability, thermal and electrical conductivity, and resistance to corrosion). Its antimicrobial property also makes the copper element a vital nutrient in our diet.

Today, it is the third most consumed metal on Earth behind iron ore and aluminum. According to the US Geological Survey, every American born in 2008 will use 1,309 pounds of the metal during their lifetime for necessities, lifestyles and health.

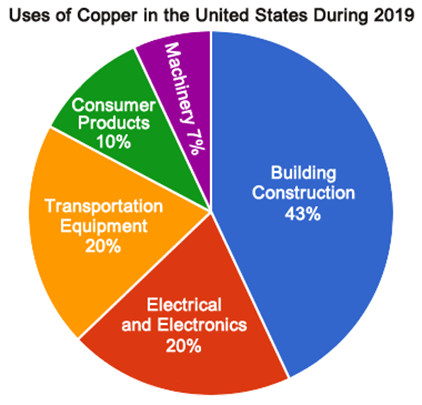

Copper is essentially a linchpin to modern society and is a valuable contributor to a variety of industries. Below are the top 5 uses of copper today:

- Building Construction

According to the USGS Mineral Commodity Summary, nearly half of the world’s copper makes its way into buildings, from downtown skyscrapers to suburban homes. The average single-family home today contains about 200 kilograms (or 439 pounds) of copper metal.

With physical properties that few metals can match, copper can be used in a wide range of building applications, from heating and plumbing to roofing and electrical wiring.

Copper’s malleability makes it easy to solder, yet it is strong enough to create the bonds needed for plumbing and electrical wiring. Copper is light and requires little maintenance, and thanks to its resistance to corrosion, it can last for several hundred years.

Copper also has low thermal expansion, making it stable and resistant to deterioration from movement. It is relatively light compared to lead, and requires little maintenance compared to other metals.

Copper is also non-magnetic and has good biofouling resistance, thus is commonly used in the construction industry to form pipes and tubing for potable water distribution and heating and cooling systems. The metal can easily be made to form complex shapes and is used as a cladding and flashing material, for gutters, downpipes and coping.

Copper can be both hot and cold worked, and joints can be formed by soldering or welding. Another big plus: copper is antimicrobial. Its resistance to bacteria, viruses and microbes plays a large role in its use in plumbing and the transportation of water.

Furthermore, copper is a sustainable metal for use in building construction, as it can be recycled time and time again without losing durability or conductivity, which means it has low life cycle impacts.

- Electronics

Copper is considered the “gold standard” for electrical wiring. Its superior electrical conductivity to other metals and abundance as a raw material make it an efficient and cost-effective choice for electronics manufacturers.

Copper’s thermal conductivity, which is 60% greater than that of aluminum, is also useful in removing heat generated by electronic components. The more heat removed from the processor, the more efficiently it will operate, with less potential for damage to other critical components.

As such, the red-colored metal is found in the electrical wiring and printed circuit boards in almost every consumer electronic product today, from mobile phones, laptops and TVs to surveillance systems, power tools and robotic vacuum cleaners.

Most printed circuit boards for electronic products are made by laminating a sheet of copper onto a flexible film and then etching away much of the copper to leave thin lines of solid copper that carry current.

- Transportation

From gas-powered cars and electric vehicles to trains and airplanes, copper also forms an essential part of our daily commute.

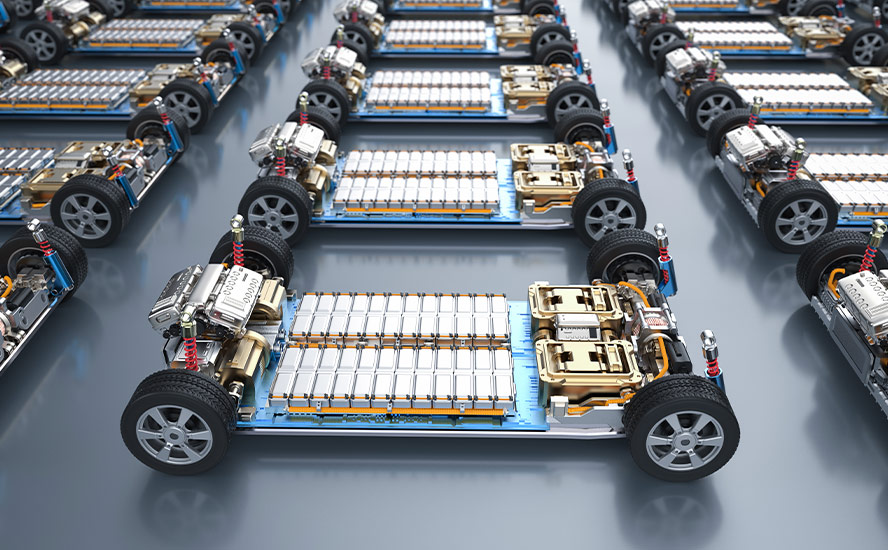

In the auto industry, copper is an essential component in brakes, bearings, connectors, motors, radiators and wiring. One conventional vehicle can contain as much as 50 pounds of copper: 40 pounds for electrical and 10 pounds for non-electrical components. Electric vehicles rely on copper’s electrical conductivity in batteries, wiring systems and charging stations.

In the railway industry, copper is used to manufacture various train parts, including motors, brakes and controls, and can also be found in electric and signal systems. A typical diesel-electric railroad locomotive uses about 11,000 pounds of the metal.

Airplanes need copper for their cooling, hydraulics and navigation, along with electrical systems. About 2% (9,000 pounds) of the total weight of a Boeing 747-200 jet plane is copper. Included in that weight is 632,000 feet of copper wire.

Copper alloys are also standard materials in shipbuilding, from bolts and rivets to propellers and condenser pipes.

- Consumer Products

When it comes to consumer products, copper’s reach and influence are even more diverse. The healthcare, jewelry and arts sectors, among many others, have long been its loyal customers.

Not only is copper essential to the human diet and is required for the growth and development of body organs, it also has antimicrobial properties that are vital to healthcare applications.

Research has shown that bacteria, viruses and yeasts cannot survive long on a copper surface, as the metal interferes with the electrical charge of a microbe’s cell membranes. Data from the US Environmental Protection Agency shows copper can kill 99.9% of E.Coli. within just two hours of exposure.

Copper’s durability also makes it an ideal ingredient for jewelries, which are usually alloyed with large quantities of metal to provide a degree of hardness, as well as aesthetic appeal. For instance, an 18K gold jewelry typically contains 75% gold, 15% silver and 10% copper. Coins also use copper and its alloys to maintain their longevity.

Copper is also “instrumental” in the creation of arts. In fact, copper alloy was used in even the oldest of musical instruments, dating back to over three millennia. Copper-based pigments were also an important ingredient in ancient paints, and the metal itself was frequently employed as a “canvas” on which Renaissance artists painted.

- Machinery

Since copper and its alloys are some of the most versatile engineering materials available, they are used in almost every industrial machinery and equipment. These include copper pipe systems, electrical motors, evaporators, condensers, heat exchangers, valves and containers for holding corrosive mediums. Corrosion-resistant copper alloys are critical materials in the fabrication of undersea installations, such as desalination machinery and offshore oil and gas drilling platforms.

The renewable energy sector is also heavily reliant on copper, an important raw material needed to build windmill turbines and solar energy systems. Compared with traditional energy systems, renewables can contain 12 times more copper metal. Wind farms use anywhere between 4 to 15 million pounds of copper, while solar photovoltaic farms require 9,000 pounds of copper per megawatt.

Richard (Rick) Mills

aheadoftheherd.com

subscribe to my free newsletter

Legal Notice / Disclaimer

Ahead of the Herd newsletter, aheadoftheherd.com, hereafter known as AOTH.

Any AOTH/Richard Mills document is not, and should not be, construed as an offer to sell or the solicitation of an offer to purchase or subscribe for any investment.

Legal Notice / Disclaimer

Ahead of the Herd newsletter, aheadoftheherd.com, hereafter known as AOTH.Please read the entire Disclaimer carefully before you use this website or read the newsletter. If you do not agree to all the AOTH/Richard Mills Disclaimer, do not access/read this website/newsletter/article, or any of its pages. By reading/using this AOTH/Richard Mills website/newsletter/article, and whether you actually read this Disclaimer, you are deemed to have accepted it.