The Dawn Of Energy Storage

2017.06.29

Burning fossil fuels releases CO2.

Bloomberg

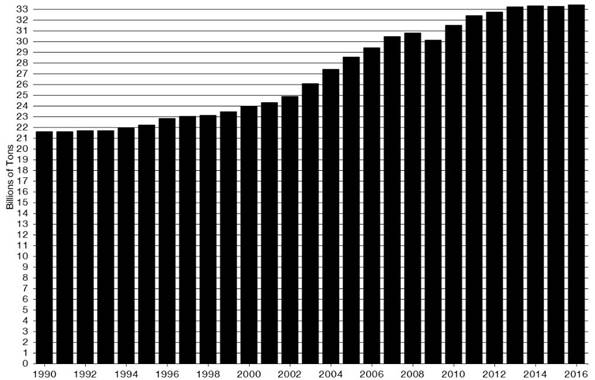

Carbon emissions from burning fossil fuels climbed to a record in 2016.

Governments around the world are looking at ways to reduce carbon emissions. Two ways we can reduce CO2 emissions are to stop burning fossil fuels to power our energy grid and by adopting electric vehicles for the transportation of people and goods.

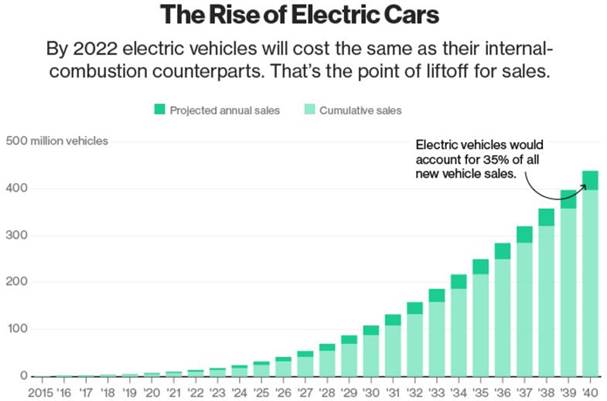

Electric vehicles are going to become very popular.

According to Bloomberg New Energy Outlook Report:

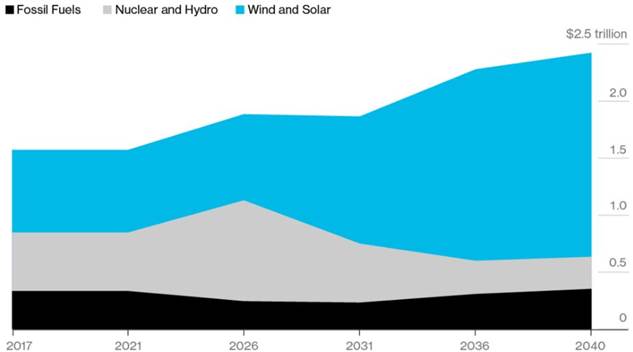

Renewable energy will dominate new investment in power to 2040.

Bloomberg, Follow the Money

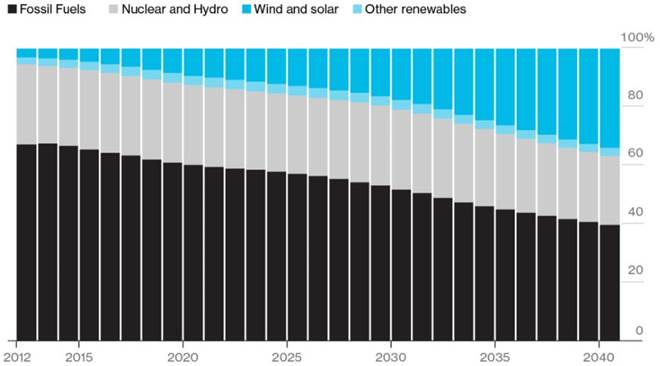

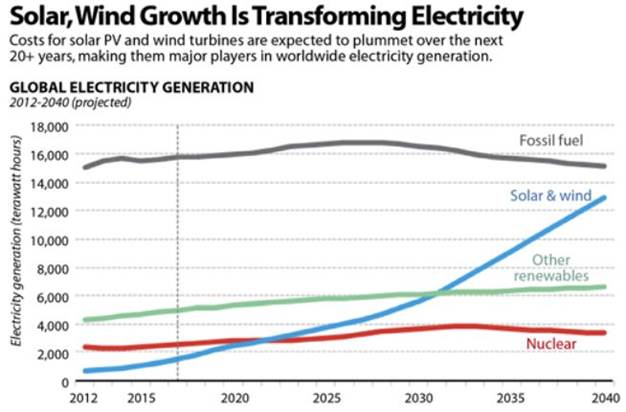

By 2040, 34% of worldwide electricity will come from wind and solar and 72% of the $10.2 trillion spent on new power generation worldwide to 2040 will be invested in new wind and solar PV plants.

Investment in renewables across the Americas averages $50 billion per year to 2040, to reach almost $1.5 trillion over 2017-40.

Large-scale solar will be cheaper than new coal plants in essentially all major economies in 5 years.

Bloomberg

Inside Climate News

Quartz Media

Renewable incompatibility

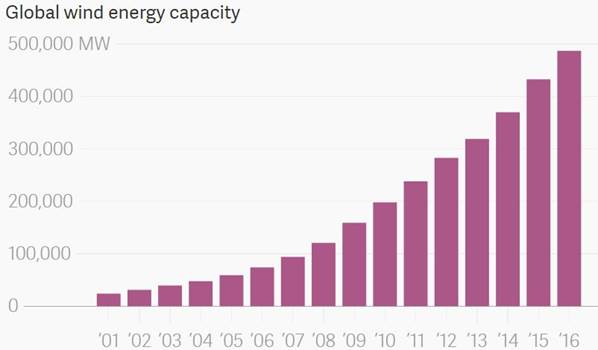

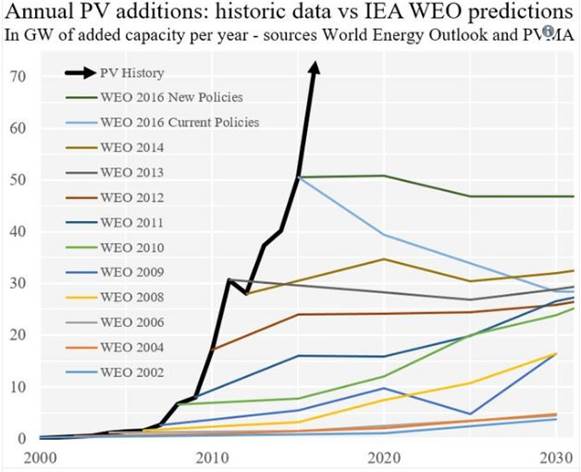

Unfortunately wind and solar energy output is not very flexible – they produce only when the sun is shining and the wind is blowing and that’s a big problem for the utilities that deliver power to consumers.

“A major constraint with such renewable sources is that energy is generated with a highly variable output in an intermittent manner. Therefore, the surplus energy is required to be stored so that it can be supplied during non-optimal generation periods such as at night time or when the wind is not blowing. Storage at a large scale has remained a major challenge.”Cision, Grid Scale Energy Storage Technologies Market

A second problem with renewable energy is most solar energy produced hits the grid between noon and 4pm. Wind blows the most during the day as the sun heats land and water.

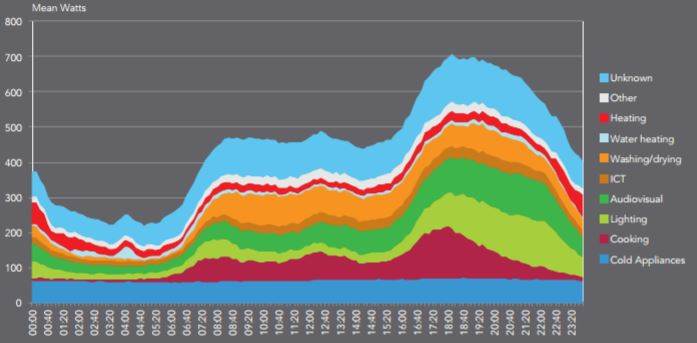

Demana – Residential power load. The Commercial sector has a very similar daily average power demand compared to the Residential sector. The Industrial sector’s demand is relatively constant.

Peak demand for electricity generally comes in the late afternoon and evening, when everyone gets home after work, turns on the lights, heating or air conditioning, cooks dinner, turns on computers and TV’s etc.

As we can see renewable energy’s output isn’t naturally compatible with our daily energy usage cycle. Utilities transmission grids need stable, predictable supplies of electricity.

Without some way to store the excess energy produced, or store the energy produced at the wrong time, limits to renewable energy’s penetration into our electricity market, and a limit to reducing carbon emissions from the burning of fossil fuels will quickly be met.

Having the flexibility of being able to store electricity, and using it when the grid needs it, has always been one of the biggest challenges for renewable power. Currently natural gas ‘peaker’ plants are used to supply energy to the grid during peak usage periods.

Batteries can achieve the needed flexibility, and are much cleaner than fracked (Hydraulic Fracturing), methane producing, not clean and green natural gas. But the batteries used need to last for more than the 300 or 400 charge/discharge cycles of lithium-ion batteries – replacing your batteries every few years is not cost efficient.

That’s where vanadium comes in. An emerging technology known as the vanadium redox-flow battery will allow utilities to store the electricity generated by large-scale wind and solar farms until it’s needed.

Vanadium Flow Battery

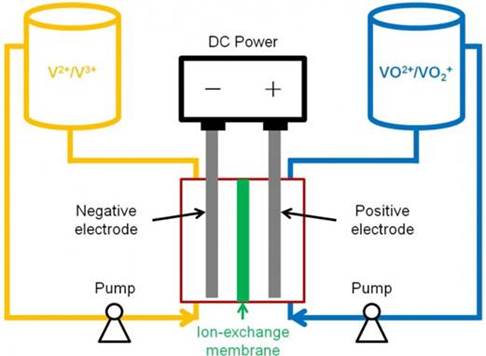

Vanadium pentoxide (V2O5) is the main ingredient, the electrolyte, in the vanadium redox flow battery (VRFB) aka the Vanadium Flow Battery (VFB) or V flow battery.

Vanadium is the only material that can convert back and forth from its various different liquid states which carry different positive charges.

In VFB batteries, liquid vanadium in two different states (V2+/V3+ and VO2+/VO2+), is pumped into a tank. A thin membrane separates the two liquids but the liquids are able to react and an electric current is generated.

The risk of cross contamination is eliminated as only one material is used. They are also safer, as the two liquids don’t mix causing a sudden release of energy. The electrolytes used never need to be replaced, they’re nontoxic and non-flammable.

Vanadium-flow batteries can be manufactured to be ‘plug-and-play’ and used with the largest utility size application down to any of the smallest micro solar/wind system.

Vanadium Flow Battery’s can store large amounts of energy almost indefinitely, which makes them perfect for wind/solar farms, industrial and utility scale applications, to supply remote areas, or to provide backup power. These batteries can also ramp up or down and pass through full charge/discharge cycles in a matter of milliseconds enabling them to deliver electricity at utility-scale over periods of four, six and even eight hours.

Rapid response and smooth ramp-up and ramp-down translate into a more efficient delivery of electricity at lower cost. These attributes are also of critical importance when it comes to recovering from grid outages and failures, which enhances the resiliency and reliability of electricity supply.

Longer discharge duration and greater scalability (you only need to add more electrolyte to add more hours of storage capacity), are other key differentiating factors of vanadium-flow batteries.

Consider – vanadium flow batteries have the advantage of a much longer life expectancy then competing battery chemistries. Controls can be upgraded much like a computer’s software/hardware, holding tanks are plastic lasting forever, the electrolyte lasts decades and is recyclable. All of these benefits allow the costs to be spread over several decades. I’ll repeat that, not over a few years – over a couple decades.

“Many people see affordable storage as the missing link between intermittent renewable power, such as solar and wind, and 24/7 reliability…For large-scale firming of wind power, our model shows that flow cells can be more economic than lithium-ion cells for all but the shortest periods (less than an hour) and are projected to continue to lead on cost through 2020.” McKinsey & Company, The New Economics of Energy Storage

Vanadium supply

Vanadium is mined mostly (85% of global production) from vanadium-bearing titaniferous magnetite found in ultramafic gabbro bodies in South Africa, north-western China, and eastern Russia.

“Surging vanadium prices so far this year are underpinned by structural supply side changes and stable, growing demand from most end uses, analysis by independent market intelligence firm Roskill has found.” Abeyla Exports,Structural supply side changes, growing demand support rising vanadium prices

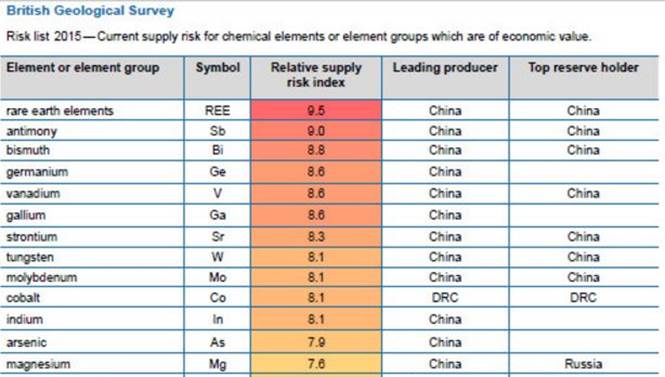

Risk List

The British Geological Society (BGS) published its first study, and ranking of the criticality of metals at the end of the last decade. Since then the BGS’s list has come to be known as the “Risk List”.

Here is the latest Risk List’s Top 13 Critical Metals. Can you spot two startling similarities they almost all share?

It would seem as if the Chinese have supply dominance in almost all of the metals the BGS deems critical to the functioning of a modern economy. Of course with supply dominance comes the ability to shut off the supply tap.

Note vanadium is the 5th ranked most critical metal.

The future of Russian imports of vanadium into the U.S. might very well depend on results of investigations regarding Russian meddling into 2016’s Presidential elections.

There are no currently operating primary vanadium mines in North America and there hasn’t been since the 1980’s. Fact is there are only a handful of vanadium deposits in North America and only a couple of these will make ‘the grade.’

Vanadium One Energy Corp. (TSX.V:VONE, FSE:9VR1)

Vanadium One Energy Corp. is looking to develop its 100% owned vanadium-titanium-iron deposit, Mt. Sorcier, into production.

In 1974 Campbell Chibougamau Mines Ltd, while looking at the potential of a Mt. Sorcier large open pit operation, published a resource estimate (resource is historical and non-43-101 compliant):

South Zone = 102,800,000 tons 27.4% Fe 1.05% TiO2. After concentration – 2.88 tons of magnetite rich rock would produce 1.0 ton of concentrate – tonnage/grade were: 35,694,444 tons @ 0.68% V2O5, 0.95% TiO2, 67.8% Fe.

North Zone = 171,000,000 tons 30.0% Fe 1.06% TiO2. After concentration – 2.88 tons of magnetite rich rock would produce 1.0 ton of concentrate – tonnage/grade were: 59,375,000 tons @ 0.57% V2O5, 1.32% TiO2, 66.2% Fe.

That’s a total, in situ historical resource of:

- 1.16b pounds of vanadium pentoxide (V2O5).

- 2.24b pounds of titanium oxide (TiO2).

- 63,507,083 tons of iron (Fe).

In 2013, a two hole drill program by Chibougamau Independent Mines Inc. confirmed Campbell Chibougamau Mines historical widths and grades.

When a metal’s, indeed any commodities supply side is constrained, in combination with strong demand, that commodity is in a situation that almost guarantees upward pressure on its price. Add in geo-political concerns about the commodities major producers and a share price rise for the junior resource company, who can potentially supply said commodity is, in this author’s opinion already baked in.

For us as retail investors the trick is to find that potential future producer.

Vanadium One’s vanadium deposit is crucial for North America’s energy storage future.

Conclusion

The use of vanadium to harden steel accounts for about 90% of the current demand for the metal – demand for vanadium is not yet driven by use in batteries. Your author believes that’s about to change with the North American grid energy storage market developing into a multi-billion dollar industry within a few years.

Energy storage is ‘the Holy Grail’ of renewable energy. Having the flexibility of being able to store electricity, and using it when the grid needs it, has always been one of the biggest challenges for renewable power. Vanadium flow batteries offer high capacity energy storage enabling wind and solar farms to out-compete fossil fuel plants for flexibility, stability and reliability.

Is the dawn of a vanadium based energy storage market on your screen?

If not, it should be.

Richard (Rick) Mills

aheadoftheherd.com

Richard’s articles have been published on over 400 websites, including:

WallStreetJournal, USAToday, NationalPost, Lewrockwell, MontrealGazette, VancouverSun, CBSnews, HuffingtonPost, Beforeitsnews, Londonthenews, Wealthwire, CalgaryHerald, Forbes, Dallasnews, SGTreport, Vantagewire, Indiatimes, Ninemsn, Ibtimes, Businessweek, HongKongHerald, Moneytalks, SeekingAlpha, BusinessInsider, Investing.com, MSN.com and the Association of Mining Analysts.

Sign up for Ahead Of The Herd’s free highly acclaimed newsletter.

***

Legal Notice / Disclaimer

This document is not and should not be construed as an offer to sell or the solicitation of an offer to purchase or subscribe for any investment.

Richard Mills has based this document on information obtained from sources he believes to be reliable but which has not been independently verified.

Richard Mills makes no guarantee, representation or warranty and accepts no responsibility or liability as to its accuracy or completeness. Expressions of opinion are those of Richard Mills only and are subject to change without notice. Richard Mills assumes no warranty, liability or guarantee for the current relevance, correctness or completeness of any information provided within this Report and will not be held liable for the consequence of reliance upon any opinion or statement contained herein or any omission.

Furthermore, I, Richard Mills, assume no liability for any direct or indirect loss or damage or, in particular, for lost profit, which you may incur as a result of the use and existence of the information provided within this Report.

Richard owns shares of Vanadium Energy Corp (TSX.V:VONE) and VONE is an advertiser on his site.

Legal Notice / Disclaimer

Ahead of the Herd newsletter, aheadoftheherd.com, hereafter known as AOTH.Please read the entire Disclaimer carefully before you use this website or read the newsletter. If you do not agree to all the AOTH/Richard Mills Disclaimer, do not access/read this website/newsletter/article, or any of its pages. By reading/using this AOTH/Richard Mills website/newsletter/article, and whether you actually read this Disclaimer, you are deemed to have accepted it.