Palladium, and Palladium One, at the forefront of new hydrogen economy

2022.01.24

As the world transitions from fossil-fueled “ICEs” to battery-powered electric vehicles, the internal combustion engine is unlikely to be resigned to the scrap heap, just yet. Gasoline vehicles and gas-electric hybrids will gradually displace more-polluting diesels, the former equipped with catalytic converters to filter out pollutants like NoX and particulate matter.

This means growing demand for materials that go into gas-powered autocatalysts, including palladium.

The platinum group metal is set for a supply deficit for the 11th straight year. Driving palladium demand are higher sales of gasoline vs diesel units and ever-increasing pollution control (GHS reduction) regulations.

Palladium use in hybrid vehicles, seen as a bridge between gas-powered cars and pure electrics, is a growing source of demand.

We’ve written much about the need for battery metals and their expected shortages in the drive to electrification and decarbonization, and the transition period when palladium will play an increasingly important role in reducing emissions as countries aim to mitigate the effects of global warming.

The hydrogen economy

However there is another solution to the problem of rising temperatures, that has so far received minimal attention in the mass media, and that is hydrogen.

Although hybrids and all-electrics are the modern vehicles of choice for the time being, some believe that lithium-ion batteries are a stop-gap technology that will eventually be replaced by hydrogen fuel cells.

The upside of hydrogen fuel cells is they produce zero emissions (just heat and water) but the downside is that to make hydrogen requires significant amounts of energy, currently being sourced from highly polluting coal or natural gas. The global production of hydrogen right now amounts to 830 million tons of carbon dioxide per year, equivalent to the CO2 emissions of the UK and Indonesia combined.

The utility of hydrogen as a fuel is also limited due to its low density, making it difficult to store, and its flammability. The relatively small number of hydrogen vehicles versus EVs, and extremely sparse hydrogen filling station infrastructure, has dented hydrogen’s consumer appeal.

According to Green Tech Media, in 2020 there were roughly 7,600 hydrogen fuel-cell cars on US roads compared to more than 326,400 EVs sold in the US in 2019.

For now, hydrogen’s use is mostly restricted to industrial applications.

Due to centralized fueling facilities where far less extensive fuel distribution networks are required, buses and utility vehicles like garbage trucks are good candidates for the incorporation of hydrogen fuel cells into the commercial vehicle market.

Remote power generation is another growing application. Caterpillar, for example, announced it will start offering Cat generator sets capable of operating on 100% hydrogen including fully renewable green hydrogen. More immediately, the company says it will launch gen-sets that can be configured to operate on natural gas blended with up to 25% hydrogen.

NASA has for years used hydrogen fuel cells to power its systems onboard and to provide drinking water for the crew.

So-called “green hydrogen” would be produced from renewable sources such as wind, solar or nuclear. The process is expensive and requires a large electrolyzer in water to split the element from oxygen.

Countries and companies however are increasingly seizing upon green hydrogen as a way of cutting greenhouse gas emissions particularly from heavy industry. Up until recently green hydrogen has been far more expensive to produce than versions made with fossil fuels, but record-high natural gas prices have driven up the costs of fossil-fueled hydrogen, making the green version more competitive.

It is estimated that green hydrogen could cost less than 1.8 euros per kilogram by 2030, compared to around €6/kg currently. So-called “grey” hydrogen produced from fossil fuels costs about €2/kg.

Europe is often on the leading edge of “green”, and there is no exception when it comes to the hydrogen economy. The European Commission, the governing body of the European Union, in 2020 called for the EU’s renewable hydrogen production to reach 1 million tonnes per year, by 2024, increasing to 5-10Mt/year by 2040. This much capacity would require the installation of 40 gigawatts of electroyzers.

Last November Reuters reported the EU and collaborating countries are likely to surpass a current target to install a combined 80GW of renewable hydrogen electrolyzers by 2030.

“That’s our aim: 40 GW of renewable electrolysers in Europe and 40 GW in Europe’s neighbourhood with export to the EU. I think it’s realistic to say we will probably outperform that by 2030,” said EU climate policy chief Frans Timmermans.

How would a greater penetration of hydrogen fuel cells affect the supply of raw materials required to make them? According to the International Platinum Group Metals Association, developments in the hydrogen sector are a demand signal for platinum, chromium and nickel.

Fuel cells are devices that convert a chemical reaction into electricity with heat and water as by-products. Platinum and ruthenium play a large role in this technology, platinum being the catalyst which converts hydrogen and oxygen to heat, water and electricity. Palladium will likely also play a role in the fuel cell, but it is unknown yet how big.

An article in ‘Materials Today’, via Science Direct, says Palladium is a unique material with a strong affinity to hydrogen owing to both its catalytic and hydrogen absorbing properties. Palladium has the potential to play a major role in virtually every aspect of the envisioned hydrogen economy, including hydrogen purification, storage, detection, and fuel cells.

Palladium (Pd) exhibits a number of exceptional properties which enable its application in a myriad of hydrogen technologies. Palladium has the ability to absorb large volumetric quantities of hydrogen at room temperature and atmospheric pressure, and subsequently forms palladium hydride (PdHx)

The superior dissociative properties of Pd enable it to serve as a catalyst to facilitate hydrogen absorption and desorption in other metal hydrides. Further, its inherent selectivity for hydrogen, fast sorption kinetics, and reversibility of hydride formation allow Pd-based alloy membranes to attain a high hydrogen gas quality at 99.99999 % purity.

According to Seeking Alpha, palladium can also be used as a substitute for carbon-supported platinum as an anode catalyst in electrolysis, and help reduce the use of platinum at the cathode too, in proton exchange membrane fuel cells.

Proton exchange membrane fuel cells are a type of fuel cell being developed mainly for transportation applications, as well as for stationary fuel-cell applications and portable fuel-cell applications.

There is evidence suggesting that using silver to manufacture fuel cells containing palladium, makes the fuel cells more effective.

Research published in the journal ‘Nature Nanotechnology’, showed that by applying an atomic layer of palladium on top of silver particles, a catalyst is created for turning formic acid into hydrogen. An article abstract explains:

“Formic acid (HCOOH) has great potential as an in situ source of hydrogen for fuel cells, because it offers high energy density, is non-toxic and can be safely handled in aqueous solution.”

Further, an Oxford University chemist wrote that he believes these improved catalysts could “enable the production of hydrogen from liquid fuel stored in a disposable or recycled cartridge, creating miniature fuel cells to power everything from mobile phones to laptops.”

Since both palladium and platinum are small markets with annual mine production of about 6 and 7 million ounces, respectively, having Pd in the mix allows for more capacity to install hydrogen transportation solutions. That is, constrained platinum supply limits the ability to deploy fuel cells widely; using palladium therefore doubles the potential.

Companies that can supply raw materials for an expanding hydrogen economy, if the technology moves in that direction, will in AOTH’s opinion, do very well.

Palladium One (TSXV:PDM, OTC:NKORF, FSE:7N11)

Palladium One Mining has been working diligently to advance two projects with mineral deposits applicable to both the battery metals designation familiar to most readers, and future-facing metals like platinum and palladium that will find a market in hydrogen fuel cells.

At Palladium One’s Tyko project in Ontario, its main metals are nickel and copper, while at the LK project in Finland, PDM is exploring for palladium, platinum, nickel, copper and cobalt.

Combined, Tyko and LK offer investors nearly equal exposure to battery metals and precious metals — the latter in the form of platinum and palladium. Note: precious metals here refers to palladium, platinum and gold.

In Finland, host country to Palladium One’s Läntinen Koillismaa (LK) PGE-Cu-Ni property, it is interesting to note that the dispersion of minerals is similarly balanced. Taking a look at the pie chart below, based on the country’s existing mineral reserve estimates, it clearly demonstrates that 53% of recovered metal to concentrate, is precious (palladium, platinum, gold) while 47% tie in directly to the battery metal theme, i.e., cobalt, copper and nickel.

LK

Months of drilling success at LK have culminated in a much-increased resource endowment, further confirming the project’s potential to host a large bulk-tonnage deposit.

At the Haukiaho zone there are significant base metals, with two-thirds of the zone’s value in nickel and copper.

The latest resource estimate of 1.2 million ounces palladium equivalent (PdEq) grading 1.15 g/t, comprises only 3 km of strike length; 2 km of strike extent, immediately east of the Haukiaho resource estimate, contains two significant IP chargeability anomalies with sufficient historical drilling to potentially be upgraded to inferred resources with modest additional drilling.

The remaining 12 km of the Haukiaho trend has not been drill tested, though widely spaced historical drilling provides a high level of confidence for potential additional nickel-copper resources to be delineated, says Palladium One.

The Kaukua Zone of LK is mostly a palladium-platinum-gold play, however it may surprise readers to learn there are significant base metal values particularly at Haukiaho, where two-thirds of the zone’s value is in nickel and copper compared to the Kaukua Zone where 66% of the value is in palladium and platinum.

Indeed Haukiaho hosts some of the highest nickel grades on the LK project. At 17 km in length, the Haukiaho trend currently represents the largest continuous patch of blue-sky potential.

As announced in a Sept. 7 news release, results from a 2,000m drill program at the Haukiaho Zone significantly increased existing resources by 32.7 million tonnes grading 1.15 g/t PdEq (palladium equivalent), for 1.21 million ounces of contained PdEq.

This resource update essentially doubles the resource endowment of the entire LK project, which now boasts 11 million tonnes of indicated resources grading 1.60 g/t PdEq (600,000 oz PdEq) and 44 million tonnes of inferred resources grading 1.19 g/t PdEq (1.7 million oz PdEq).

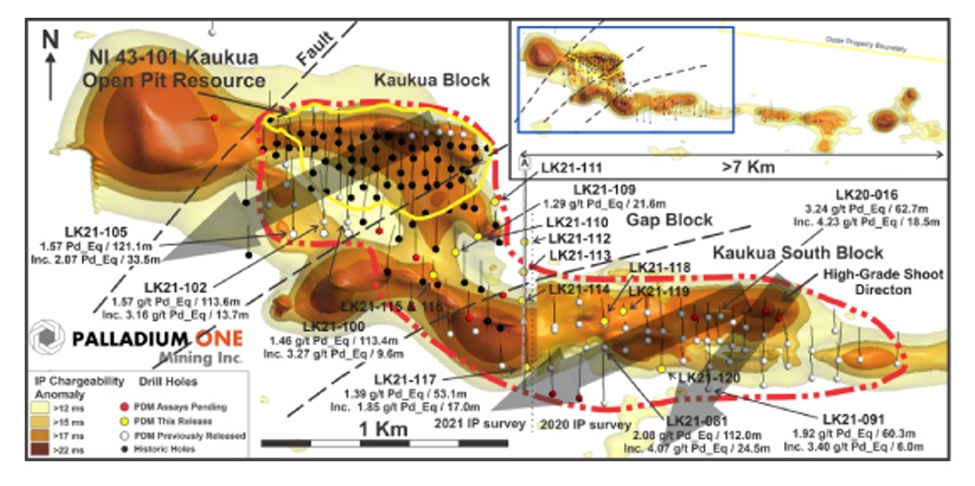

The company recently reported its widest intercept to date, in a hole drilled southwest of the area where the 2019 open-pit resource estimate at Kaukua was compiled.

All three holes spread over 220 meters laterally intersected the down-plunge, high-grade ‘Core Zone’, with hole LK21-05 reporting the best grades.

The hole brought up drill core assaying 2.1 grams per tonne (g/t) palladium equivalent (PdEq) over 33.5 meters, within 1.6 g/t PdEq over 121 meters. Individual samples graded up to 16 g/t PdEq over 0.6m.

The Core Zone of the Kaukua open pit has been extended 250 meters to the southwest, and it remains open at depth.

“We have extended the ‘Core Zone’ of the Kaukua Deposit 250 beyond the current conceptual open-pit and hole LK21-105 is among the thickest intercepts to date within the Kaukua Deposit and adds significant tonnage to our existing resource endowment,” said Derrick Weyrauch, Palladium One’s President and CEO, in the Jan. 11 news release.

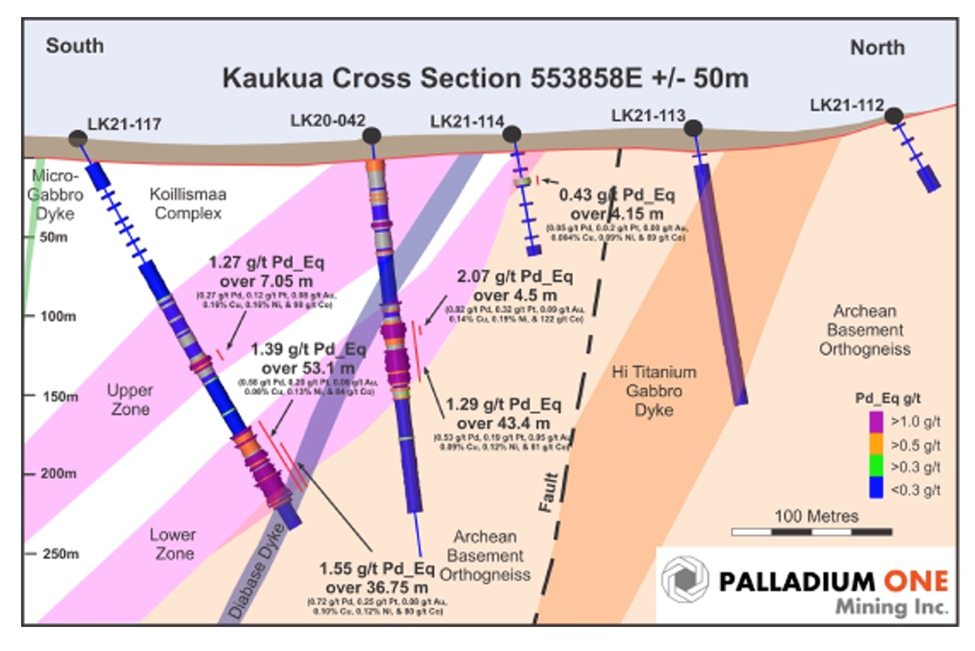

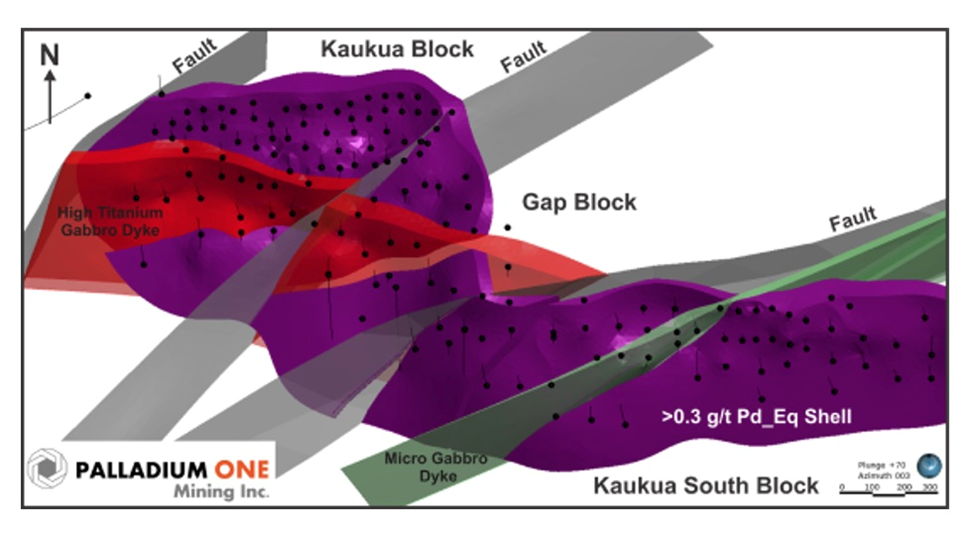

The company followed that up with the results of in-fill drilling released on Thursday, Jan. 20. As Palladium One was drill testing the area between the Kaukua open pit and the Kaukua South Zone, it encountered a new zone it has dubbed Gap. The Gap Zone is considered to be an important area for future resource definition, seeing as it could connect Kaukua and Kaukua South into a larger open-pit mine.

Assay highlights were:

- 1.3 g/t PdEq over 21.7 meters, including 2.2 g/t PdEq over 4.4m;

- 1.3. g/t PdEq over 27.8m, with a higher-grade 1.7 g/t PdEq over 6.3m;

- 1.4 g/t PdEq over 53.1 meters, including 1.8 g/t PdEq over 17m.

“We have made significant progress infilling the area between the Kaukua Open Pit Resource and Kaukua South. Though Gap Zone mineralization is thinner, it could play a significant role in joining Kaukua and Kaukua South into one larger and more efficient Open Pit mine,” Weyrauch stated, in the Jan. 20 news release.

The company notes the Greater Kaukua area is now divided into three blocks separated by northeast-trending faults — Kaukua Open Pit, Kaukua South and Gap Zone. The first two blocks dip to the south and have core zones with thicknesses over 100m, whereas the Gap Zone dips west and has mineralized thicknesses in the 10 to 20-meter range.

These results bolster the company’s belief that it could add a significant amount of open-pit resources to the new NI 43-101 resource estimate expected in the first quarter.

Tyko

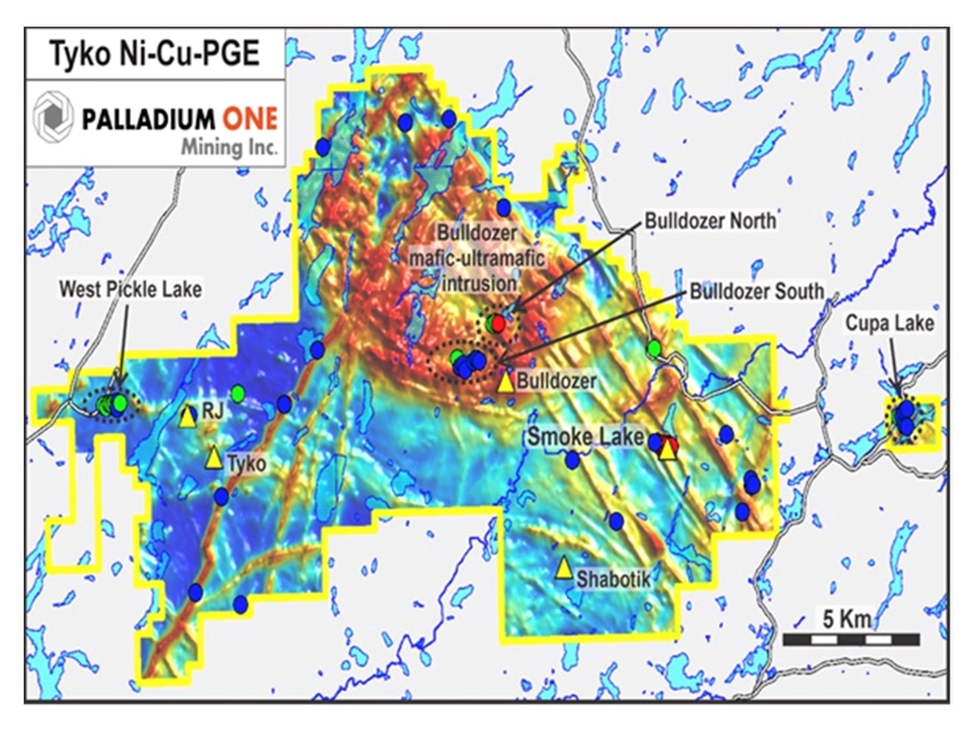

Palladium One also continues to outline a high-grade nickel-copper system at its Tyko Ni-Cu-PGE project in Ontario, where a second-phase drill program in 2021 and an announced expansion increases the size of the property by over a fifth.

All 13 holes drilled at the Smoke Lake target intersected magmatic sulfides, with widths ranging from 1 to 15 meters. A second-phase, 2,000m drill program started last April, following up on high-grade hits of 9.9% nickel equivalent (NiEq) over 3.8m. A number of high-grade intersections were reported, all near surface.

Excited as Palladium One is about its nickel results, there are also notable copper and nickel occurrences, in particular the RJ and Tyko zones located about 18 km west of Smoke Lake. Drilling in 2015 returned several intercepts over 1% nickel + copper with a high of about 1.5% Ni + Cu.

The 7,000-hectare mafic-ultramafic Bulldozer intrusion, which has seen virtually no geological mapping nor exploration, also has significant historical copper showings.

Conclusion

Recently cashed up from a $4.35 million financing, Palladium One is ready to continue exploring Tyko and LK, building upon its considerable 2021 news flow, including a brand new resource at Kaukua expected within the first quarter.

PDM has already amassed 11 million tonnes of indicated resources at LK, grading 1.60 g/t PdEq (600,000 oz PdEq) and 44 million tonnes of inferred resources grading 1.19 g/t PdEq (1.7 million oz PdEq).

Tyko’s Smoke Lake target continues to advance with the strike of the known mineralization growing to 430 meters. An IP geophysical survey is planned for this winter to continue to chase the mineralization, which includes 5.0% nickel equivalent over 1.4 meters and up to 891 ppm copper and 142 ppm cobalt in soils at the Bulldozer Intrusion. In addition to Smoke Lake, Palladium One believes there are new zones of nickel-copper mineralization yet to be discovered. The project was awarded the 2020 Bernie Schnieders Discovery of the Year by the Northwestern Ontario Prospectors Association.

Between both properties, we see Palladium One and its highly motivated management team as a “complete” energy metals company. To review, Tyko’s main metals are nickel and copper, while at the LK project in Finland, PDM is exploring for palladium, platinum, nickel, copper and cobalt.

All of these metals have a role to play in the new green economy. Even better, their markets are bullish. Nickel prices have risen from about $4 a pound in July 2017, to the current $10.18. On Thursday they rallied to a 10-year high of $24,000 a ton. According to Bloomberg, the nickel market reached its tightest point since 2007 earlier this week, after a plunge in LME stockpiles. Two other factors helping nickel prices are China’s monetary easing, and tensions over Ukraine raising the possibility of disruptions to nickel exports from Russia, a key producer of the base metal.

Spot copper has more than doubled from just over $2/lb in April 2020, to the current $4.52. Palladium, despite having an off year in 2021 due to the global chip shortage which crimped consumption of the metal used in the manufacture of catalytic converters, is back to levels seen last June, after falling as low as $1,786/oz last September. Morgan Stanley said in a December note that a rebound in auto production this year should create upside for palladium; the bank sees palladium prices this year averaging $2,100/oz.

Copper is a crucial component of electrical vehicle motors, wiring and charging stations. Nickel and cobalt are used in the most popular lithium-ion battery chemistry for electric vehicles, NMC batteries. But electric vehicles won’t replace fossil-fueled powered ones quickly. Gasoline-run cars and trucks with their palladium-containing autocatalysts are needed as a bridge technology, to replace diesels, and will be demanded for many years to come, stoking demand for palladium and challenging miners to supply enough of the mineral.

Hybrids are another, more advanced bridge technology. Despite the increased penetration of EVs, hybrids are projected to outpace electric cars for years. They require a greater concentration of precious metals (platinum, palladium, rhodium) than those found on gasoline-only cars.

Platinum and palladium will become increasingly important in hydrogen fuel cell technology, platinum being the catalyst that converts hydrogen and oxygen to electricity. Palladium’s ability to absorb large quantities of hydrogen means it has future applications in almost every aspect of the hydrogen economy, including hydrogen purification, storage, detection, and fuel cells. Palladium can also be employed as a substitute for platinum in fuel cell catalysts and in proton exchange membrane fuel cells used in transportation applications.

Palladium One’s updated resource estimate at Kaukua, expected this quarter, should provide a stock price catalyst going forward, as the company continues field work at its properties containing a potent mix of energy and precious metals.

Palladium One Mining

TSXV:PDM, OTC:NKORF, FSE:7N11

Cdn$0.24, 2022.01.20

Shares Outstanding 248m

Market cap Cdn$62.7m

PDM website

Richard (Rick) Mills

aheadoftheherd.com

subscribe to my free newsletter

Legal Notice / Disclaimer

Ahead of the Herd newsletter, aheadoftheherd.com, hereafter known as AOTH.

Please read the entire Disclaimer carefully before you use this website or read the newsletter. If you do not agree to all the AOTH/Richard Mills Disclaimer, do not access/read this website/newsletter/article, or any of its pages. By reading/using this AOTH/Richard Mills website/newsletter/article, and whether you actually read this Disclaimer, you are deemed to have accepted it.

Any AOTH/Richard Mills document is not, and should not be, construed as an offer to sell or the solicitation of an offer to purchase or subscribe for any investment.

AOTH/Richard Mills has based this document on information obtained from sources he believes to be reliable, but which has not been independently verified.

AOTH/Richard Mills makes no guarantee, representation or warranty and accepts no responsibility or liability as to its accuracy or completeness.

Expressions of opinion are those of AOTH/Richard Mills only and are subject to change without notice.

AOTH/Richard Mills assumes no warranty, liability or guarantee for the current relevance, correctness or completeness of any information provided within this Report and will not be held liable for the consequence of reliance upon any opinion or statement contained herein or any omission.

Furthermore, AOTH/Richard Mills assumes no liability for any direct or indirect loss or damage for lost profit, which you may incur as a result of the use and existence of the information provided within this AOTH/Richard Mills Report.

You agree that by reading AOTH/Richard Mills articles, you are acting at your OWN RISK. In no event should AOTH/Richard Mills liable for any direct or indirect trading losses caused by any information contained in AOTH/Richard Mills articles. Information in AOTH/Richard Mills articles is not an offer to sell or a solicitation of an offer to buy any security. AOTH/Richard Mills is not suggesting the transacting of any financial instruments.

Our publications are not a recommendation to buy or sell a security – no information posted on this site is to be considered investment advice or a recommendation to do anything involving finance or money aside from performing your own due diligence and consulting with your personal registered broker/financial advisor.

AOTH/Richard Mills recommends that before investing in any securities, you consult with a professional financial planner or advisor, and that you should conduct a complete and independent investigation before investing in any security after prudent consideration of all pertinent risks. Ahead of the Herd is not a registered broker, dealer, analyst, or advisor. We hold no investment licenses and may not sell, offer to sell, or offer to buy any security.

Richard does not own shares of Palladium One Mining (TSXV:PDM). PDM is a paid advertiser on his site aheadoftheherd.com

Legal Notice / Disclaimer

Ahead of the Herd newsletter, aheadoftheherd.com, hereafter known as AOTH.Please read the entire Disclaimer carefully before you use this website or read the newsletter. If you do not agree to all the AOTH/Richard Mills Disclaimer, do not access/read this website/newsletter/article, or any of its pages. By reading/using this AOTH/Richard Mills website/newsletter/article, and whether you actually read this Disclaimer, you are deemed to have accepted it.