For US to stand a chance in the global battery arms race, developing a graphite supply is a must

2021.11.24

In a few years’ time, we will look back at 2021 as the turning point in human history where vehicle electrification became no longer just a consumer choice, but a necessary step towards achieving net-zero emissions.

The recent COP26 climate change conference served as both a reminder and a “call to action” that the global transition from gas-powered cars towards plug-in vehicles is far from complete.

Transportation currently makes up 28% of the global emissions, so the scope for improvement remains significant.

Of course, the plan of “going green” and cleaning up the planet requires significant action from the world’s two largest economies, the US and China.

President Biden is already pushing forward on climate-oriented programs, including the $1.1 trillion infrastructure spending package recently passed by Congress.

Vehicle electrification is a major part of the legislation’s focus. It would provide $7.5 billion for low-emissions buses and ferries, and aims to deliver thousands of electric school buses to districts across the country. Another $7.5 billion is expected to go towards building a nationwide network of plug-in EV chargers.

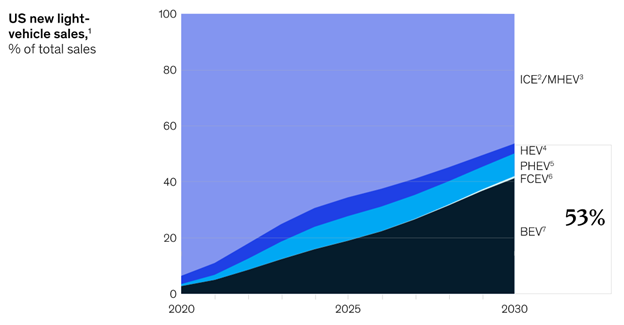

This past August, Biden signed an executive order requiring that half of all US new vehicle sales be electric by 2030.

China, too, is moving forward rapidly on its plans to electrify and decarbonize its roads, looking to make all new vehicles sold in the country “eco-friendly” by 2035. China is the world leader in electric vehicles and battery production.

EV Market Growth

As expected, the global energy transition would create strong tailwinds for the EV market for years and even decades into the future.

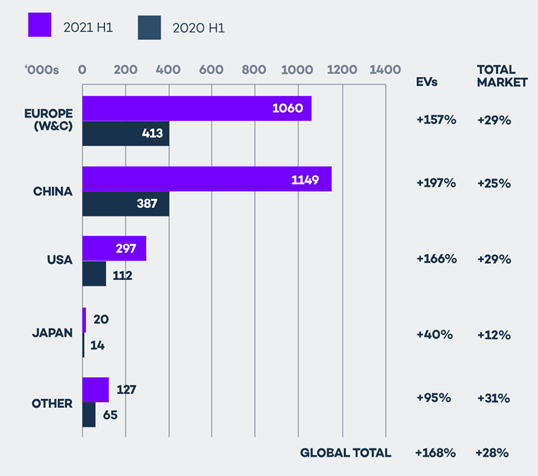

Power Technology, known for its research on the energy sector, reports that EV sales have already more than doubled worldwide in the first half of 2021, increasing by 160% compared to H1 2020. The 2.6 million units sold, 1.1 million of which were in China, represent 26% of total new car and truck sales globally.

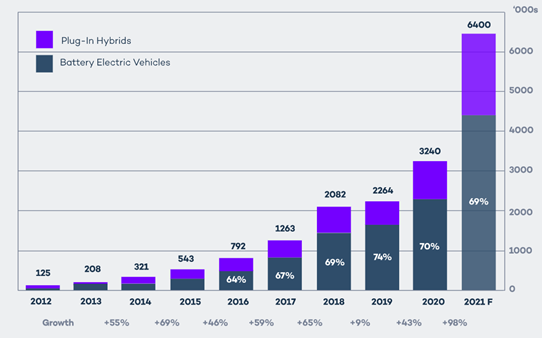

An analysis from IDTechEx quoted by the publication forecasts EV sales in 2021 are on track to surpass 5 million passenger cars. “If they do, it will mean an astonishing growth rate of ~86% CAGR since 2011,” the report reads.

Virta, which claims to be the fastest-growing electric vehicle charging platform in Europe, operating in over 30 countries, is more aggressive in its 2021 EV sales forecast.

“Carried by a decarbonization challenge most leading nations now take seriously, 2021 is a game changer in the history of EV sales and it is expected that 6.4 million vehicles (EVs and PHEVs combined) will be sold globally by the end of the year. It would then represent a 98% year over year increase,” the company states in a report titled ‘The Global Electric Vehicle Overview in 2022: Statistics and Forecasts’.

Projecting further out, Virta cites the International Energy Agency’s (IEA) Global EV Outlook 2021, whose Stated Policies Scenario suggests that by 2030, the global EV stock (excluding two- and three-wheelers) could reach nearly 145 million and account for 7% of the total vehicle fleet.

The more ambitious EV30@30 campaign envisions, plainly, 30% of all vehicles becoming electric by 2030, putting global sales at 43 million, or almost double that of the Stated Policies Scenario.

It isn’t only electric cars and trucks that are increasing in popularity either. According to Virta: “From public transportation to e-scooters: The entire transport industry is turning electric.”

For example, in the US, e-bike sales have more than doubled in 2020, whereas in Europe, electric scooters are becoming more mainstream. The IEA’s Global EV Outlook 2021 found more than 100 European cities have already started operating e-scooters.

Heavy-duty electric truck registrations were up 10% in 2020, which is significant considering that large ICE trucks are responsible for 70% of CO2 emissions. Electric buses have also been increasing since 2020, with Virta noting that China registered 78,00 new e-buses in the past year, adding to a global fleet of 600,000 in 2020.

More impressive EV sales statistics can be found in a recent report by McKinsey & Company.

Starting with 2020, the consultancy notes that global sales exceeded pre-pandemic levels by the third quarter, with Europe and China achieving fourth-quarter sales increases of 60% and 80%, respectively, over the previous quarter, helping to drive global EV penetration to an all-time high of 6%. (higher than Virta’s 4.6%)

McKinsey’s numbers only go to the second quarter of 2021, when it says EV sales in the US increased by nearly 200% compared to Q2 2020, contributing to a domestic penetration rate of 3.6% during the pandemic. The next report should deliver similar or even better growth figures.

McKinsey believes EV sales will continue increasing, fueled by government policies including the Biden administration’s stated goal that half of all new vehicle sales by 2030 be zero-emission; state-level adoption of credit programs; tougher emissions standards; and increasing electrification commitments from OEMs.

More Battery Minerals

For all the talk of electrification, nothing can be achieved without ensuring there is enough supply of the metals used to power these vehicles.

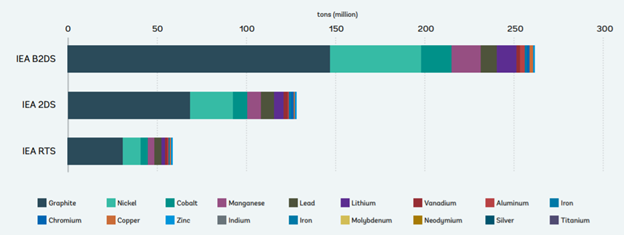

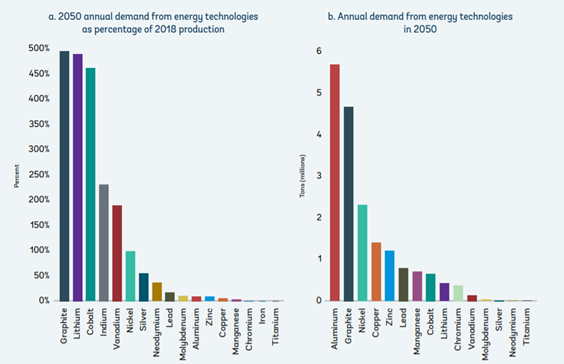

A 2020 World Bank report entitled ‘The Mineral Intensity of the Clean Energy Transition’, estimated that production of minerals underpinning the clean energy shift such as lithium and graphite would have to increase by nearly 500% by 2050 to meet global demand for renewable energy.

Obviously these include lithium, a key ingredient for making EV batteries, which is set to endure an unprecedented shortage of supply in the coming years. Global miner Rio Tinto has previously said even if they had another 60 lithium mines, that wouldn’t fill the supply-demand gap.

With EVs expected to take up over half of the total vehicle sales as early as 2030, that would require as much as 3 million tonnes of lithium annually, compared to the 400,000 tonnes of lithium per year being mined currently.

Even if you combine all existing operations plus future projects around the world, that’s only 1 million tonnes of future lithium, still a 2-million-tonne gap that needs to be filled. Bloomberg NEF research shows that over five times more lithium is needed in 2030 compared to current levels.

Another battery mineral that is not in the spotlight as much but is also facing severe supply concerns is graphite. Did you know: Graphite is the only material that can be used in the lithium-ion battery anode, there are no substitutes.

According to the World Bank, graphite accounts for nearly 53.8% of the mineral demand in batteries, the most of any. Lithium, despite being a staple across all Li-ion batteries, accounts for only 4% of total demand.

An average hybrid-gasoline electric vehicle carries up to 10 kg of graphite, while a plug-in EV has seven times that amount – around 70 kg.

For every million electric vehicles, which is only about 1% of the new car market, we need in the order of 75,000 tonnes of natural graphite, representing a 10% increase in flake graphite demand.

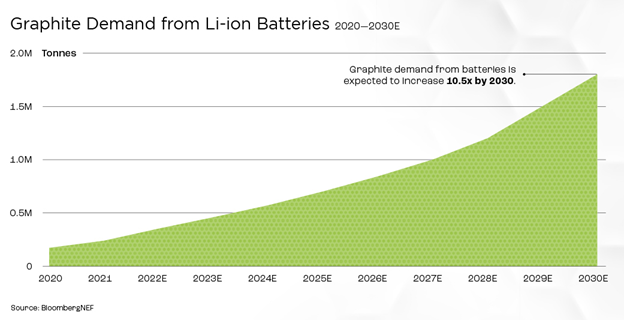

The EV battery market alone is projected to consume well over 1.6 million tonnes of flake graphite per year, resulting in a ten-fold increase in demand by 2030. This is worrisome considering that total graphite mined in 2020 for all uses, including lump graphite for pencils and graphite used in nuclear reactors, was only 1.1 million tonnes.

It is estimated that the natural flake graphite market could reach a deficit as soon as 2023, with few new sources being developed around the world.

At the moment, nearly all graphite processing takes place in China because of the ready availability of graphite there, weak environmental standards and low costs. Approximately 59% of the world’s natural graphite production last year came from China, making it a dominant player in every stage of the supply chain.

Meanwhile the US, despite boasting a large EV market, has no domestic production, meaning it has to fully rely on its main economic rival (and its other trading partners) for battery-grade graphite supply (see below). Such a level of dependence can be considered both unsustainable and uneconomical.

This is why the US is not looking to develop its own “mine to battery” supply chain, which would include a cost-competitive and environmentally sustainable source of graphite.

A White House report on critical supply chains showed that graphite demand for clean energy applications will require 25 times more graphite by 2040 than was produced worldwide in 2020.

On February 24, 2021, President Joe Biden signed an executive order (EO) aimed at strengthening critical US supply chains. Graphite was specifically identified as one of four minerals considered essential to the nation’s “national security, foreign policy and economy.”

Fortunately, there is plenty of North American graphite for local consumption, if industry and government can find the collective will to make it happen.

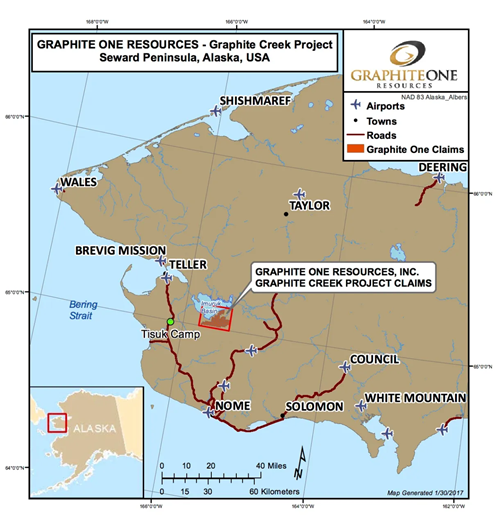

As far as we know, the Kigluaik Mountains on Alaska’s Seward Peninsula in Alaska hosts at least one deposit with the size and grade to meet the nation’s growing need for graphite in Li-ion batteries.

Graphite One

Earlier this year, the Federal Permitting Improvement Steering Committee (FPISC) granted High-Priority Infrastructure Project (HPIP) status to Graphite One Inc. (TSXV:GPH, OTCQX:GPHOF), which is aiming to develop America’s first high-grade producer of coated spherical graphite (CSG) integrated with a domestic graphite resource at Graphite Creek, Alaska.

The HPIP designation allows Graphite One to list on the US government’s Federal Permitting Dashboard, which ensures that the various federal permitting agencies coordinate their reviews of projects as a means of streamlining the approval process.

Graphite Creek is the highest-grade and largest known flake graphite deposit in North America, spanning a distance of 18 km.

The project is envisioned as a vertically integrated enterprise to mine, process and manufacture high-quality CSG for the lithium-ion electric vehicle battery market. Graphite One aims to become the first US vertically integrated domestic producer to do so.

The latest resource estimate (March 2019) for Graphite Creek showed 10.95 million tonnes of measured and indicated resources at a graphite grade of 7.8% Cg (graphitic carbon), for some 850,000 tonnes of contained graphite. Another 91.9 million tonnes were tagged as inferred resources, with an average grade of 8.0% Cg containing 7.3 million tonnes.

A Preliminary Economic Assessment (PEA) supports a 40-year operation with a mineral processing plant capable of producing 60,000 tonnes of graphite concentrate (at 95% purity) per year. On a pre-tax basis, the project has a net present value of $1.03 billion using a 10% discount rate, with an internal rate of return (IRR) of 27%.

Once in full production, Graphite One’s proposed graphite products manufacturing plant — the second link in its proposed supply chain strategy — is expected to turn graphite concentrates into 41,850 tonnes of battery-grade coated spherical graphite and 13,500 tonnes of graphite powders per year. A location in the Pacific Northwest is being considered.

Graphite Creek Field Program

Last month, Graphite One reached a significant milestone in its project development with the completion of the 2021 field program at Graphite Creek.

The field program included infill and step-out core drilling in the resource area, plus additional core and sonic drilling for geotechnical data collection in the proposed mill site and dry tailings/waste rock storage areas.

Other work included access route engineering, surface water and groundwater hydrology studies, wetlands mapping and aquatic life surveys.

A total of 2,052 meters were drilled during the 2021 program including 1,695 meters of HQ core drilling and 357 meters of sonic drilling. Results from 8 core holes completed in the resource area are expected to be released in Q1 2022.

According to Graphite One, the 2021 core drilling in the deposit area continued to encounter visible graphitic mineralization over wide intervals that are consistent with previous drilling results, as reported in 2019 and in the 2017 PEA.

Additional core drilling was completed to collect detailed geotechnical information for open-pit and mills site engineering, and for groundwater investigations.

The 5 sonic holes completed in the dry tailings/waste rock storage area will provide detailed geotechnical information to advance the engineering of these facilities, the company says.

Overall, this drill program will generate additional information to update the resource model and provide technical data for the project’s Feasibility Study (FS), expected to be initiated in 2022.

Meanwhile, the Preliminary Feasibility Study (PFS) is progressing and scheduled for release later this year.

“With the recent C$21 million in funding, our efforts have progressed towards completion of the PFS for the largest known and highest-grade graphite deposit in the United States,” Anthony Huston, CEO of Graphite One, stated in the Oct. 13 news release.

“We are very pleased with the successful execution of the 2021 field program, as historical drilling coupled with the new data clearly demonstrates the predictability and consistency of high-grade, near-surface graphite.

“With the concepts and conclusions outlined in the PEA suggesting a 40-year mine life, the Graphite Creek deposit continues to show potential to be an essential long-life component of the graphite supply chain, one of four critical minerals that are on the US National Defense stockpile list.”

While the PEA demonstrated the project’s economic viability, the company expects these further studies, with their optimized plans for the mine and processing facilities, to further improve the economics.

Conclusion

With US President Joe Biden finally putting pen to paper on the $550 billion bipartisan infrastructure bill, the American EV revolution is now moving at full throttle. It’s almost certain that by 2030, electric-powered vehicles will dominate the US roads.

However, this could only materialize once there is a reliable and sufficient supply of metals used to build EV batteries. The fact that a mineral like graphite, which has no substitutes in a battery anode, has always been imported by the US raises alarms for the future state of the industry.

Placing graphite among the list of critical minerals was a good start, and with the slew of investments to “electrify” the economy and get the nation closer to its end-of-decade climate goals, that spells opportunity to prospective mine developers.

Graphite One is a company on the move with the largest and highest-grade flake graphite deposit in the United States.

What it has discovered so far though is only a small portion of the geological trend under consideration. I believe Graphite Creek will become a mine and that its production will supply a large percentage of US domestic graphite demand. I therefore see it as an important link in America’s burgeoning “mine to battery” supply chain.

Graphite One Inc.

TSXV:GPH, OTCQX:GPHOF

Cdn$2.04, 2021.11.23

Shares Outstanding 83.3m

Market cap Cdn$170m

GPH website

Richard (Rick) Mills

aheadoftheherd.com

subscribe to my free newsletter

Legal Notice / Disclaimer

Ahead of the Herd newsletter, aheadoftheherd.com, hereafter known as AOTH.

Please read the entire Disclaimer carefully before you use this website or read the newsletter. If you do not agree to all the AOTH/Richard Mills Disclaimer, do not access/read this website/newsletter/article, or any of its pages. By reading/using this AOTH/Richard Mills website/newsletter/article, and whether you actually read this Disclaimer, you are deemed to have accepted it.

Any AOTH/Richard Mills document is not, and should not be, construed as an offer to sell or the solicitation of an offer to purchase or subscribe for any investment.

AOTH/Richard Mills has based this document on information obtained from sources he believes to be reliable, but which has not been independently verified.

AOTH/Richard Mills makes no guarantee, representation or warranty and accepts no responsibility or liability as to its accuracy or completeness.

Expressions of opinion are those of AOTH/Richard Mills only and are subject to change without notice.

AOTH/Richard Mills assumes no warranty, liability or guarantee for the current relevance, correctness or completeness of any information provided within this Report and will not be held liable for the consequence of reliance upon any opinion or statement contained herein or any omission.

Furthermore, AOTH/Richard Mills assumes no liability for any direct or indirect loss or damage for lost profit, which you may incur as a result of the use and existence of the information provided within this AOTH/Richard Mills Report.

You agree that by reading AOTH/Richard Mills articles, you are acting at your OWN RISK. In no event should AOTH/Richard Mills liable for any direct or indirect trading losses caused by any information contained in AOTH/Richard Mills articles. Information in AOTH/Richard Mills articles is not an offer to sell or a solicitation of an offer to buy any security. AOTH/Richard Mills is not suggesting the transacting of any financial instruments.

Our publications are not a recommendation to buy or sell a security – no information posted on this site is to be considered investment advice or a recommendation to do anything involving finance or money aside from performing your own due diligence and consulting with your personal registered broker/financial advisor.

AOTH/Richard Mills recommends that before investing in any securities, you consult with a professional financial planner or advisor, and that you should conduct a complete and independent investigation before investing in any security after prudent consideration of all pertinent risks. Ahead of the Herd is not a registered broker, dealer, analyst, or advisor. We hold no investment licenses and may not sell, offer to sell, or offer to buy any security.

Richard owns shares of Graphite One Inc. (TSXV:GPH). GPH is a paid advertiser on his site aheadoftheherd.com

Legal Notice / Disclaimer

Ahead of the Herd newsletter, aheadoftheherd.com, hereafter known as AOTH.Please read the entire Disclaimer carefully before you use this website or read the newsletter. If you do not agree to all the AOTH/Richard Mills Disclaimer, do not access/read this website/newsletter/article, or any of its pages. By reading/using this AOTH/Richard Mills website/newsletter/article, and whether you actually read this Disclaimer, you are deemed to have accepted it.