FluroTech provides LP’s rapid and effective inhouse cannabis testing

Imagine walking into your local liquor store to pick up a bottle of wine. You have a few favorite varietals in mind, but you don’t trust the alcohol percentages you see on the labels. Last week you bought a Cabernet-Sauvignon from Chile, supposedly 14% alcohol, but it took three glasses to feel anything. The week earlier though, another brand of Cab-Sauv from Chile packed such a punch, you fell asleep after two glasses. Both claimed to be 14% alcohol by volume (ABV). What gives?

Of course, this is an imagined scenario; standardization of ABVs for all types of alcohol has been in place since the end of Prohibition. Not so for the burgeoning cannabis industry.

Nine months into legalization, the variability of potencies of both marijuana- and hemp-based plants is a problem associated with legalized cannabis in Canada and half a dozen US states.

Indeed the “cross-variability” of a particular strain or batch is an issue that affects everyone from the grower to the consumer.

Canadian start-up FluroTech (TSX-V:TEST, OTCQB:FLURF) is offering a solution to the problem. The Calgary-based Company has an extremely accurate means of measuring both the strength of cannabis and its purity – the latter referring to a product’s low or non-existent levels of impurities like mold, pesticides and heavy metals.

Need for testing

Currently there is no universal method for testing cannabis products. But as regulated cannabis markets continue to emerge in North America (Canada and 11 US states now have legal marijuana, sold for medicinal and recreational purposes), there is a growing need for a system of rapid and effective cannabis testing.

The testing market is pegged at $300 million in Canada, just over double that in the United States, and $2.75 billion worldwide.

FluroTech is the first mover in this space with portable spectroscopy analytical testing devices. An industry disruptor, there are currently no public or private companies with similar technologies for cannabis testing.

The testing device, called CompleTest™ uses spectroscopy and fluorescence to measure the content of a given attribute including CBDA, THCA the acid form of THC and CBD which is present in cannabis plants before combustion. The Company will be releasing mold, pesticides and heavy metals in the coming months as well as THC and CBD for extracts and processed products. The device has been commercialized.

TEST’s revenue model involves selling testing devices to licensed cannabis producers, retailers, extractors and companies that do drug testing. The buyer would purchase a testing device plus a “scope” that slots into the device for each type of test – THCA/CBDA, pesticides, heavy metals, etc. Each test or assay (“lab kit”) would be priced individually or bundled per month.

The Company is also pursuing workplace testing, the use of CompleTest™ in law enforcement, the hemp market for CBD products, and “biomarking” whereby an attribute is placed into every plant grown by a licensed producer, that can be tracked throughout the plant’s life all the way through processing to the end use product consumed.

Of great interest to the dispensary and consumer is the THC level, or in the case of CBD products, the amount of cannabidiol. Some cannabis consumers are wanting the higher-level THC content found in the “flower” (bud) of the plant, while others prefer something less potent. Same with buyers of CBD products.

But testing has its advantages far before the final test for potency is conducted on the strain that is distributed to dispensaries.

Unlike getting a sample tested in a lab, CompleTest™ can return a result within minutes, versus days or weeks. This is a big advantage to cannabis growers because it vastly reduces wait times. It also allows growers to test plants at any time during the growing cycle, not only the final stage when the product must be tested to meet government regulations before being sold.

Frequent, regular testing enables growers to identify pests or contaminants (heavy metals, insecticides, herbicides, mold), early on, and to optimize their crops, making them more profitable. It also gives consumers more confidence that the company they are buying from, delivers a quality, contaminant-free product that also offers consistent dosing (potency). The worst kind of publicity for an LP is the discovery of a tainted crop that has to be pulled from shelves.

The need for testing has become even more relevant in Canada’s run-up to the legalization of cannabis edibles in December. The new regulations will include inhalable extracts, foods, beverages and topical applications like lotions. Ottawa is reportedly restricting the potency of edibles to 10 milligrams of THC – the low limit has invited criticism from those who say it won’t do away with the black market, where pot-infused foods can contain up to 80 mg. THC.

Over-precaution aside, the edibles market is large enough to make an LP salivate. According to a report from BDS Analytics, North American consumers spent US$1 billion on edibles in 2017. The market is expected to grow to $4.1 billion by 2022.

Cross-variability; an industry problem

As mentioned, the state of cannabis testing right now is unreliable, with different testing laboratories failing to produce consistent results. Even if labs use the same technology – High-Performance Liquid Chromatography (HPLC) – which separates and evaluates a mix of chemicals in a liquid solution – the results can vary wildly, discrediting the cannabis testing sector.

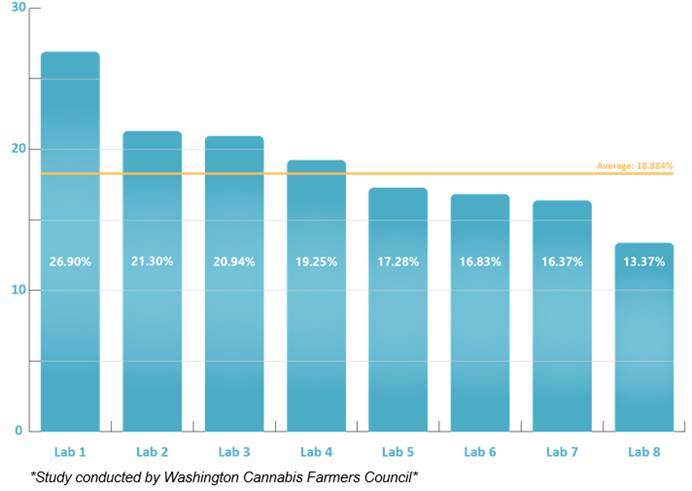

The same batch of cannabis tested by different test labs will also return significant variability. Different labs have different protocols and calibration techniques, resulting in different recorded potencies.

Consider a study done by the Washington Cannabis Farmers Council. A cannabis sample was sent to eight labs in the state, which legalized recreational weed in 2012. The THC potency results varied from 13.37% on the low side to a high of 26.9% – showing a variability of 100%!

The cannabis industry is well-aware of the problems with HPLC testing.

“There are a tremendous number of questions around the reliability of the data that’s being generated by cannabis laboratories,” said Jeremy Applen, owner of New Mexico’s first state-approved testing laboratory.

“If you don’t have robust standards around cultivation, manufacturing, or distribution, you don’t really know what chain of events occurred prior to that product being identified as potentially adulterated.”

Therefore, as the cannabis industry continues to grow, with more and more states legalizing and even the US federal government mulling it, there is an increasing demand for testing labs to perform potency, safety and quality tests on ever-increasing quantities of product.

To do that, the industry will need to come up with more reliable testing methods, regulations and standards. And solve the cross-variability puzzle.

There are several aspects to the problem, which we will aim to summarize here.

The first thing to understand is that the plant being tested is not in itself homogenous. That means when cannabinoids are extracted into a liquid for analysis, it’s difficult to find a batch where all the ingredients are the same. For example, the trichomes – small hair-like crystals on the marijuana bud – may be distributed differently from one batch to another.

Second, while Health Canada-approved labs may use the same HPLC technology and instrumentation, their testing methods may differ, producing different results.

And third, there may be variation between testers, with some employees of test labs lacking training or experience, or testing equipment may not be used properly. The old saying “garbage in, garbage out” is relevant here.

The end result is the plant sample sent by the grower, may come back with an unexpectedly high or low level of THCA or CBDA which can be frustrating to the grower, especially since they’ve been waiting a week to 10 days for the results. It may even result in a crop being destroyed in the case of finding contaminants, at great expense to the grower.

Another issue is differing “cannabinoid standards”. In Canada, when a new lab wants to get certified by Health Canada to conduct cannabis testing, it must first go to a certified lab to obtain standards of testing ie. how high of a concentration they are allowed to test eg. 1mg/ml. The new lab will then develop its own method of testing based on the certified lab’s cannabinoid standards. Different labs adhere to slightly different standards, thereby allowing for differentiation in test results.

Then there are the problems with the labs themselves. Forbes mentions this in an article it pithily headlines ‘Cannabis lab testing is the industry’s dirty little secret.’ In the United States this means that “not all labs are created equal,” meaning that some labs are more “industry-friendly” than others, by rejecting few batches. This is facilitated by a lack of government oversight. Forbes states:

The labs themselves aren’t inspected or graded by any agencies and customers have no idea whether or not products were tested at a reputable lab.

Some believe that the problem is standardization, but there are plenty of state standards — the real problem is enforcement.

Marijuana with a higher THC content is generally considered by consumers to be of higher quality, therefore it commands a higher price. This can affect how a batch is tested. The higher price incentivizes growers to produce marijuana with more THCA, and some unscrupulous labs can help the grower to achieve its goal. Or an unethical licensed producer could send in another batch for testing, higher in THCA, than its own, without the lab knowing it.

Tightening up the math

As a first mover in the cannabis testing space with a disruptive testing technology, FluroTech has taken it upon themselves to run a battery of tests in order to show cross-lab variability and the consistency/ repeatability of its testing protocol.

The Company has gone out to different licensed producers and tested, so far, about 60 marijuana strains. It ran the tests internally using several testers on different CompleTest™ machines. FluroTech also sent its samples to an outside lab, to confirm the results were the same as the “listing” (potency) of that particular strain.

“Rather than just relying on the standard that came in we run a test the same way every time, we double check by looking to outside sources, and by comparing different producers to different producers’ listings, we’re tightening up our math,” says COO Rex Kary.

Cross-variability experiment

The Company also compared its own internal testing to that of outside laboratories. TEST first obtained two marijuana samples from a dispensary. It divided the samples into ground-up plant material, the flower/ bud, and an extract. Those samples were then sent to five different labs, which measured the potency of the samples according to their testing methodology.

FluroTech ran its own in-house testing of the samples, then compared the results to those of the five outside labs. It expected to prove both cross-variability and the better accuracy of its own testing. The Company was also hoping to prove that its results are repeatable, by comparing samples tested at FluroTech’s facilities over the course of several weeks. The results (above) speak for themselves – besides being cheaper FlorTech’s CompleTest™ was faster as it’s done in house in a matter of minutes and showed superior consistency between tests.

There are some results missing on the above chart. FluroTech asked (paid) for 24-hour turnaround time. That was 3 weeks ago.

Earlier, a marijuana strain tested 25 times by CompleTest™ showed the device’s capability of delivering the same results time and again, with very low variance. The ability to replicate results provides LP’s the ability to know the potency and purity of their product before harvesting.

Low barrier to entry

As a company, FluroTech isn’t only about the science behind cannabis testing; while the lab techs pore over samples and test results, its sales team is taking CompleTest™ on the road.

FluroTech’s beta program involves leaving CompleTest™ units at licensed producers (LP) for them to try out. The hope is for all of those “betas” to convert into sales. The sales territory begins in Western Canada, to be followed by a pivot to Eastern Canada, before spreading state-side for hemp testing and even into the Caribbean.

Good old-fashioned networking has proved fruitful. The sales team has attended all the major conventions, including the recent C-45 Quality Summit in Winnipeg. They won best new technology at a Vancouver conference in January debuting the testing device.

“Most people in the industry already have a fairly strong understanding of the problems within cross-lab variability, so it’s very refreshing for them to hear something so accurate like our machine can be brought into their facility,” said Zack Kary.

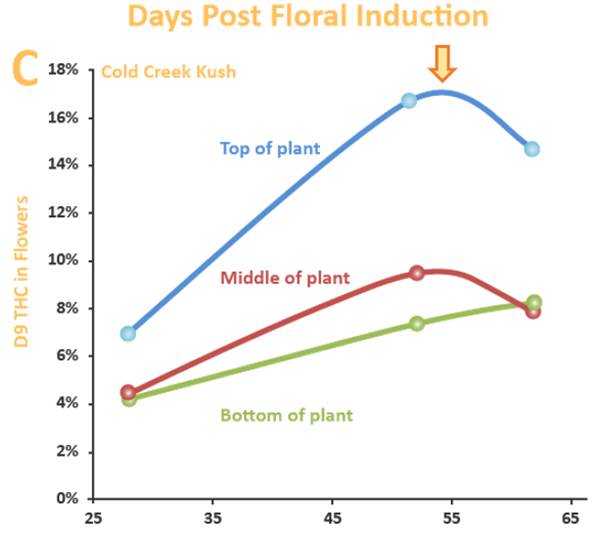

The ability to test plants throughout the growth cycle is also well received.

“This gives them the ability to really rein in on the exact point of harvest that would benefit them. So, keeping the highest potency, not wasting any energy on nutrients, water, light, that sort of thing, and really just optimizing crops. That’s the main thing I’ve been seeing LPs get really excited about.”

Eric Entzsaid in talking to LPs, informing them of CompleTest™’s ability to reduce bottlenecks, time constraints and loads on QA staff, “it’s not even a matter of sales”, meaning the conversation is more about filling a need:

“It’s very low barrier to entry in terms of getting in with these LPs because they all, like Zach said, understand it. They say it’s lab one versus lab two,” in terms of getting different results.

He noted that LPs tell him a 1% bump in plant potency represents a 9% increase in revenue from that crop. “When they hear that what we have can save them time, money, and effort, well, it’s very simple.”

Matt Gibsonchose consistency of results as an important attribute of CompleTest™ that LPs are looking for: “To be able to have that in your own hands gives you as a licensed producer much more confidence in the product that you’re going to eventually sell.”

Finally, Mauricio Airias, who leads the FluroTech team of R&D scientists,noted the flexibility of having a simple to operate testing instrument in-house, that can quickly test several samples, in different growing periods and conditions, without reliance on an outside lab, is a real game-changer for growers he has spoken with.

“It is perfect for them to have something on hand that is easily available that pretty much any person with small training can start using the equipment and get reproducible and accurate data. I think that’s the most important aspect of the instrument.”

CompleTest™ enables continuous testing – croptimization – which means a plant’s peak potency period is more easily identified. A 1% increase in THC potency = 8.3% increase in revenue

Of course, cost saving is a key part of the value proposition. Out of a 55- to 60-day grow cycle, having an in-house testing device and testing protocol can potentially knock five days off the harvest cycle. That can significantly cut a producer’s costs, because they are not wasting nutrients, electricity, or taking up space in their grow room with plants that could be harvested.

Conclusion

FluroTech (TSX-V:TEST, OTCQB:FLURF) has a disruptive testing technology, CompleTest™, with the ability to transform the cannabis sector, through a marked improvement in the reliability and repeatability of cannabis testing. If successful, the Company could be the first to create a standardized testing regime for marijuana and hemp plant material, that could one day equal the alcohol industry.

I am following developments at TEST with interest as it continues to prove its game-changing technology in a booming industry that appears to be the perfect fit.

FluroTech

TSX-V:TEST, OTCQB:FLURF

Cdn$0.36 June 18th

Shares Outstanding 54.2m

Market cap Cdn$19.5m

FluroTech website

*****

Richard (Rick) Mills

Ahead of the Herd Twitter

Ahead of the Herd FaceBook

Legal Notice / Disclaimer

This document is not and should not be construed as an offer to sell or the solicitation of an offer to purchase or subscribe for any investment. Richard Mills has based this document on information obtained from sources he believes to be reliable but which has not been independently verified. Richard Mills makes no guarantee, representation or warranty and accepts no responsibility or liability as

to its accuracy or completeness. Expressions of opinion are those of Richard Mills only and are subject to change without notice. Richard Mills assumes no warranty, liability or guarantee for the current relevance, correctness or completeness of any information provided within this Report and will not be held liable for the consequence of reliance upon any opinion or statement contained herein or any omission. Furthermore, I, Richard Mills, assume no liability for any direct or indirect loss or damage or, in particular, for lost profit, which you may incur as a result of the use and existence of the information provided within this Report.

Richard owns shares of FluroTech (TSX.V:TEST). TEST is an advertiser on Richards site, aheadoftheherd.com

Legal Notice / Disclaimer

Ahead of the Herd newsletter, aheadoftheherd.com, hereafter known as AOTH.Please read the entire Disclaimer carefully before you use this website or read the newsletter. If you do not agree to all the AOTH/Richard Mills Disclaimer, do not access/read this website/newsletter/article, or any of its pages. By reading/using this AOTH/Richard Mills website/newsletter/article, and whether you actually read this Disclaimer, you are deemed to have accepted it.