Evanesce takes ‘dirt-to-dirt approach’ to replace plastic packaging for a truly circular economy – Richard Mills

2023.06.20

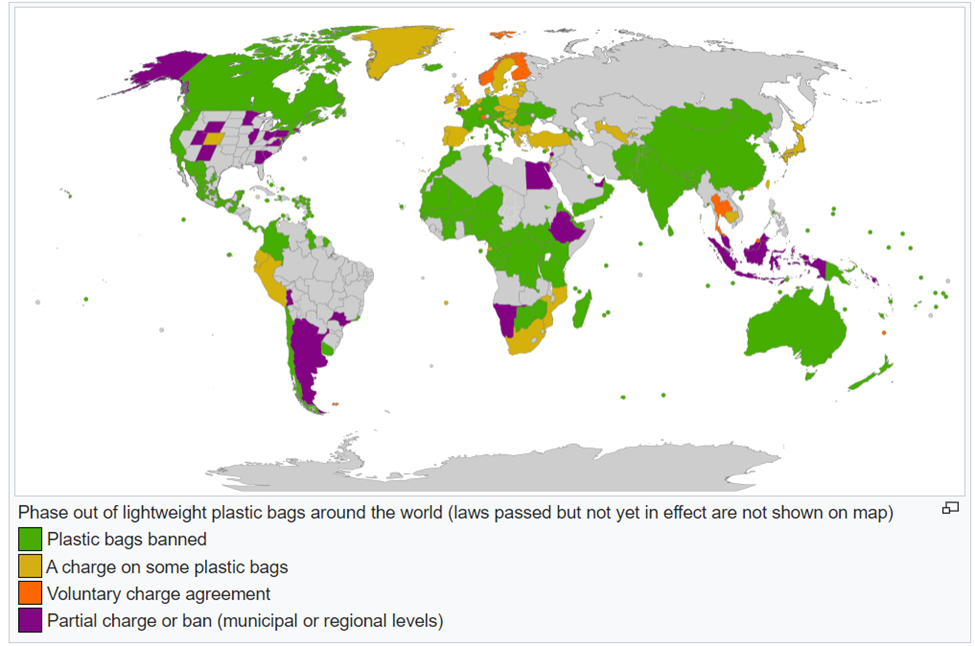

In many parts of the world, consumers are still adjusting to grocery shopping or buying takeout food without plastic bags.

Here in Canada, most stores, supermarkets and restaurants have stopped offering plastic bags to customers, even for an extra charge. Instead, you may get the option of purchasing a reusable bag made of cotton or fabric. Some places, if you’re lucky, would give out paper bags, but they are also places that follow the “bring your own bag” rule.

All this is part of a growing trend in the wake of Canada’s new regulations on single-use plastics.

In June 2022, the federal government announced a ban on single-use plastics including checkout bags, cutlery, food service ware, ring carriers, stir sticks and straws. The ban on the manufacture and import of these products took effect December 2022, and the sale of these items is expected to go into force later this year.

In addition, Canada will prohibit the export of plastics in the same six categories by the end of 2025. Ottawa has also set a target date of 2030 for halting the flow of plastic waste.

Like most countries implementing similar bans, the move was part of a national effort to achieve zero plastic waste by 2030, according to Environment and Climate Change Canada.

Every year, Canadians throw away at least 3 million tonnes of plastic waste, with only 9% being recycled and the rest ending up in landfills, waste-to-energy facilities or nature, Environment Canada estimates.

According to Juan José Alava, research associate at the Ocean Pollution Research Unit at the University of British Columbia, Canada’s single-use plastic ban represents “an important step” that could eliminate an estimated 1.3 million tonnes of plastic waste annually that’s hard to recycle.

Beyond banning single-use plastics, Alava said the next step should be to develop solutions to try to eliminate plastic bottles and toxic chemicals that are used for the production and manufacture of plastics.

One of the ways to do that is to replace conventional petroleum-based plastics with those made from biobased inputs that can be recycled in existing technologies.

The problem can also be solved by using biodegradable resins such as PLA, PHA, and starch blends, which are compostable and would help reduce the waste in landfills as well as methane emissions.

Plant-based Technology

One company that is at the forefront of this is Evanesce, which designs and manufactures sustainable packaging solutions using the latest advancements in material science.

Headquartered in Vancouver, Evanesce is currently developing an innovative technology to replace single-use plastics and expanded polystyrene (EPS) foam, commonly known today as Styrofoam.

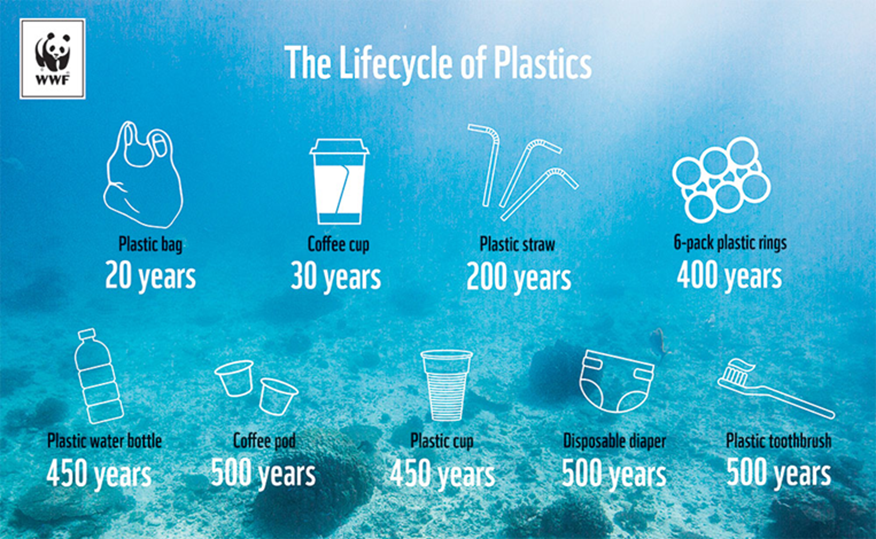

Its patented technology, called Molded Starch, is designed to produce plant-based packaging alternatives that can decompose in 90 days or less. In comparison, single-use plastic and Styrofoam waste found in food packaging can take 500 years or more to decompose.

According to Evanesce’s website, its 100% compostable, 100% plant-based range of Molded Starch products are expected to arrive in 2023. These can include meat trays, meal trays, food containers and five-section meal trays.

Once it hits the market, the Molded Starch product line would undoubtedly have the potential to disrupt the industry. The technology is centered on an optimum combination of starch and fiber from upcycled plant materials; the products contain no microplastics or toxins, and are marine and soil biodegradable.

As the name suggests, the technology is based on molding starch into the desired product. The patent covers a wide range of fibers that are all derived from food waste — from rice and wheat husks to barley and hemp, all may be used in the starch fiber end product. They look and feel identical to polystyrene, but are 100% compostable.

Such revolutionary technologies could go a long way towards solving a major environmental problem and health threat that we have largely ignored for more than a century.

World’s Plastic Problem

Plastic has been filling up our landfills for decades, or incinerated, thus contributing to land/ ocean/air pollution, and carbon emissions.

If plastic were a country, it would be the fifth-highest emitter in the world. That’s because 99% of plastic is made from fossil fuels. A significant portion of emissions comes from the extraction and transportation of fuels that create plastic, including methane from natural gas, considered 28 times more potent than carbon dioxide.

Cracking plants that refine fuel and convert it to plastic are also extremely harmful to the environment. At the production stage, polyester, polyamide and acrylic, used in textiles, have the highest level of emissions.

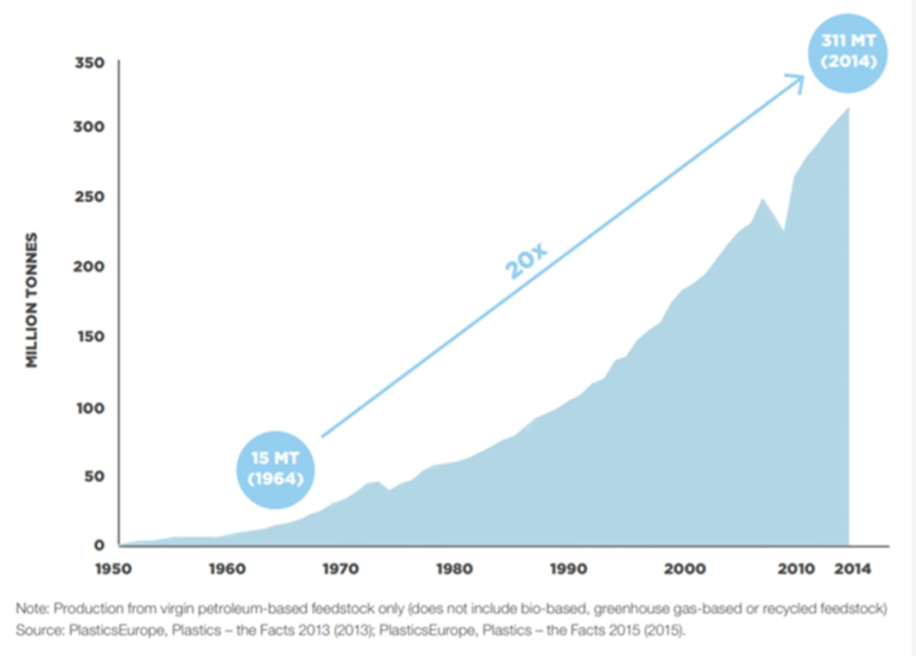

Over the years, plastic has followed a hockey stick-shaped growth trajectory. We make 190 times more plastic than we did in 1950.

A 2016 study by the World Economic Forum estimates that global plastic production went from 15 million tonnes in 1964 to 311 million tonnes in 2014 — a 20-fold increase during a 50-year period. Now, the world produces more than 380 million tonnes of plastic, up to 50% of which are for single use.

Production is expected to at least double again over the next two decades, then quadruple by 2050, the WEF predicts.

Despite the proliferation of curbside recycling programs, regional eco-centers, and an increasingly aware and motivated public, very little plastic is recycled, around 10% according to most estimates. Another 12% is incinerated, reducing it to ash, gas and heat. The other 79% make their way to a landfill or escape into the environment.

It is estimated there are over 150 million tonnes of plastic in the ocean. Around 8 million tonnes enter the seas every year — the equivalent of dumping a truckload of plastic garbage every minute.

National Geographic says the problem of discarded plastic is so severe, that if nothing is done, by 2050 the oceans will contain more plastic than fish, ton for ton.

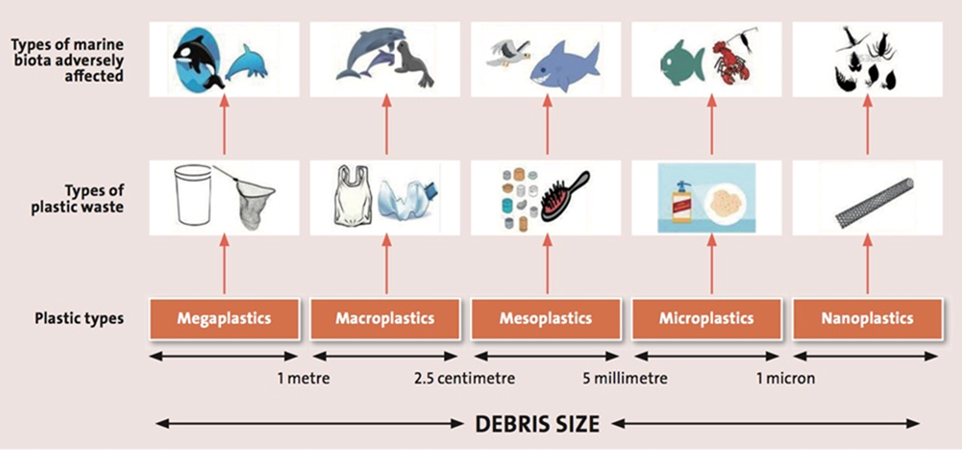

It has become a much-discussed topic, and the subject of several docuseries, revolving around the harmful effects of minute plastic fragments, called microplastics and nanoplastics, on plants, fish, sea birds, mammals, and eventually, humans at the top of the food chain.

The problem stems from the fact that plastic is virtually indestructible. A trait that was once sold to consumers as a virtue, has become a vice, due to the ubiquity of plastic especially in the marine environment.

Most plastic has a very long lifespan. Plastic bags, for example, can take up to 20 years to decompose, while takeaway coffee cups, despite being mostly paper, have a plastic lining that can last for 30 years.

Other items, including coffee pods, disposable diapers, and plastic toothbrushes, will be in landfills for five centuries!

What makes plastic so problematic? The answer comes down to chemistry. Plastic is a polymer molecule consisting of repeating identical units (homopolymer) or different sub-units in sequences (copolymer).

Plastics are further categorized as thermoplastics, which soften when heated and can be molded; or thermosets, which cannot be molded or heated. Both types cause pollution in marine environment.

Plastics also contain chemicals to improve their properties that cause harm when they enter the food chain.

Today, microplastics are deeply entrenched in the global ecosystem. They have been detected in lakes and seas, in the sediments of rivers and deltas, and in the stomachs of the smallest and largest organisms, from zooplankton to whales. One study found that every square kilometer of the world’s oceans has 63,320 plastic particles floating on the surface.

Microplastics in 2022 were found in beef and pork for the first time, as well as in the blood of cows and pigs. The tiny plastic particles are thought to originate in the feed that the animals consume.

One study looking for synthetic particles in sea turtles found microplastics in the guts of all 102 turtles that were examined. They have also been detected in quantities of up to 273 particles per pound of sea salt, 300 fibers per pound of honey, and around 109 fragments per liter of beer.

A common way for microplastics to move up the food chain is to be first consumed by algae that are eaten by water fleas, which in turn become fish food.

The problem is not only the micro/ nanoplastics, but the pollutants they carry with them. When plastics move through the food chain, the attached toxins also move, and accumulate in animal fat and tissue through a process called bio-accumulation. Chemicals added to the plastic during the production process can leach from the plastic into the body of the animal that has eaten them.

Humans, at the top of the pyramid, are consuming an amount of plastic the size of a credit card every week!

Industry Shakeup

Putting a stop to the manufacture of single-use plastics would at least ensure that fewer and fewer harmful materials make their way into the ecosystem. But this is just the first step.

The next step is to replace conventional plastic products and Styrofoam with bio-friendly alternatives. This not only requires innovation, but perhaps also a big shakeup within the industry.

The packaging industry of today is extremely mature and dominated by global players who compete in a commoditized manner selling similar plastic and polystyrene (Styrofoam) packaging on closest to market cheapest to client basis. But all that is crumbling at the edges due to a hodgepodge of government regulations: a nightmare for the national brands and franchisees whose models depend on identical branding, quality of product and seamless distribution.

The early cracks and fissures in the system are being filled with localized companies whose product solutions are narrow and targeted at only the latest bans in the district. There are definitely some interesting and amusing attempts to recreate the market.

We are seeing alternatives to plastic as far-fetched as being derived from seaweed and mussel shells to the more common pressed fiber (paper) and bagasse (sugar cane byproduct). The latter of which has gained some traction, particularly in the regional markets where companies can compete in their backyard with low shipping costs because their manufacturing costs are much higher than the incumbents.

However, most of these young companies cannot produce a wide product offering and have focused on specific items to simplify the certification process and costs. Building up a manufacturing plant to produce dozens of products in different sizes at scale is capital intensive and requires years of moderate growth to get to contention for full product offerings for anything other than a localized restaurant, bar and deli markets.

A secondary problem has been created by this rush to fill the regulatory vacuum. Virtually all of these pressed fiber products must be coated with something to keep the food moisture from deteriorating the packaging. Early versions were coated with a plastic film which rendered the fiber products non-compostable and contaminated the landfills with microplastics as the thin films broke down defeating the purpose of the units in the first place.

An even more serious problem has now swept into the market replacing plastic coatings with PFAS (polyfluoroalkyl substances, or commonly known as forever chemicals) which until recently was not regulated against use in the food packaging industry.

However, the gig is up for many of these early vendors as PFAS has now been recognized as an extremely hazardous chemical carcinogen that the body cannot rid itself of. The chemical manufacturers are reeling from lawsuits, with Dupont Chemours and Corteva settling a $1.18 billion dollar lawsuit last week and 3M settling a $10 billion suit while deciding to fight the larger $143 billion class action suit.

These catalysts have moved market buyers for alternatives to find solutions from within the biopolymer market which utilizes modified starch compounds PLA and PHA to produce products with a similar look, touch and characteristics to plastic but they are 100% biodegradable. The vast majority of the producers in this category are based in Asia but product reliability between vendors is sketchy at best.

Evanesce’s Unique Solution

This is where a company like Evanesce comes into the picture. The company has taken a unique approach of positioning itself as a leading solution provider to the alternative packaging industry, targeting the single-use plastics (SUP) market that is worth some $980 billion per year.

Evanesce’s business model focuses on the most advanced technological developments in the field, firstly through its own research center, but additionally in joint ventures and partnerships with established manufacturers.

Its journey begins here in North America, where it has set up a joint venture partnership with Minima, the world’s leading provider of polylactic acid (PLA) used to make biodegradable plastic. Based in Taiwan, Minima has attracted some of the largest chemical and distribution company players, including China-based Formosa Plastics and Japan’s Mitsui & Co., one of the largest logistics and trading companies in the world.

Through their joint venture, Evanesce is providing a PLA technology that is 81% owned by Evanesce, and 19% by Minima. The JV has set up its first operating plant in South Carolina to manufacture straws made from corn starch that are 100% compostable within 90 days, and will become the initial cornerstone of Evanesce’s business development.

As we mentioned earlier, Evanesce’s 100% plant-based, 100% compostable technology can be molded into a diverse range of products. What we didn’t mention is that they cost just half of other eco-friendly alternatives.

In fact, its biopolymers are cheaper than paper, better than plastic and BPI-certified compostable. It is also already in the production stage, leveraging Minima’s 17 years of experience perfecting the manufacture of a full suite of single-use plastic alternatives.

Last October, Evanesce opened its first US production facility in Hampton County, South Carolina, where it will produce eco-friendly food service products using renewable resources such as corn starch. The 15,000-square-foot facility has the ability to manufacture millions of compostable straws per day.

The next line of products coming out in the third quarter this year is designed to replace the Styrofoam used in meat packaging.

Conclusion

In a world filled with plastic, having 100% compostable food packaging products is very much welcomed, and it’s down to companies like Evanesce to continue to deliver.

In a recent podcast interview, Douglas Horne, CEO and founder of Evanesce, talked about the importance of using compostable packaging as a solution to recycle food waste. A key takeaway from it is that ‘dirt-to-dirt approaches are more sustainable and circular” when it comes to recycling.

A major problem with recycling food waste, he says, is the usage of multiple bins, and compostable packaging like those developed by his company allows people to put things in a single bin and dispose food waste for composting, which otherwise ends up in landfills.

“To attain a truly circular economy, compostable biopolymer plastics are part of the solution,” Horne said in a media release last year following Canada’s plastic ban following last year’s announcement.

He added that: “The only way to reduce plastic is to use and make less plastic. Composting offers a viable and logical step forward not only to reduce, and hopefully eliminate plastic packaging and serviceware, but in creating a truly circular economy.”

With governments continuing to do their part in limiting single-use plastics that are at best 10% recycled, there is at least a $980 billion market up for grabs. More opportunities could be presented down the line as global leaders and industries take a uniform approach to cut down the surging plastic pollution.

According to a 2022 Organisation for Economic Co-operation and Development report, the amount of plastic waste is projected to almost triple by 2060, with around half ending up in landfill and less than a fifth recycled.

Earlier this month, country delegations, NGOs and industry representatives gathered in Paris this week for the second round of UN talks on what could become the first global treaty to curb plastic pollution. The plan, if all goes smoothly, is to reach a legally binding pact by the end of next year.

Richard (Rick) Mills

aheadoftheherd.com

subscribe to my free newsletter

Legal Notice / Disclaimer

Ahead of the Herd newsletter, aheadoftheherd.com, hereafter known as AOTH.

Please read the entire Disclaimer carefully before you use this website or read the newsletter. If you do not agree to all the AOTH/Richard Mills Disclaimer, do not access/read this website/newsletter/article, or any of its pages. By reading/using this AOTH/Richard Mills website/newsletter/article, and whether you actually read this Disclaimer, you are deemed to have accepted it.

Any AOTH/Richard Mills document is not, and should not be, construed as an offer to sell or the solicitation of an offer to purchase or subscribe for any investment.

AOTH/Richard Mills has based this document on information obtained from sources he believes to be reliable, but which has not been independently verified.

AOTH/Richard Mills makes no guarantee, representation or warranty and accepts no responsibility or liability as to its accuracy or completeness.

Expressions of opinion are those of AOTH/Richard Mills only and are subject to change without notice.

AOTH/Richard Mills assumes no warranty, liability or guarantee for the current relevance, correctness or completeness of any information provided within this Report and will not be held liable for the consequence of reliance upon any opinion or statement contained herein or any omission.

Furthermore, AOTH/Richard Mills assumes no liability for any direct or indirect loss or damage for lost profit, which you may incur as a result of the use and existence of the information provided within this AOTH/Richard Mills Report.

You agree that by reading AOTH/Richard Mills articles, you are acting at your OWN RISK. In no event should AOTH/Richard Mills liable for any direct or indirect trading losses caused by any information contained in AOTH/Richard Mills articles. Information in AOTH/Richard Mills articles is not an offer to sell or a solicitation of an offer to buy any security. AOTH/Richard Mills is not suggesting the transacting of any financial instruments.

Our publications are not a recommendation to buy or sell a security – no information posted on this site is to be considered investment advice or a recommendation to do anything involving finance or money aside from performing your own due diligence and consulting with your personal registered broker/financial advisor.

AOTH/Richard Mills recommends that before investing in any securities, you consult with a professional financial planner or advisor, and that you should conduct a complete and independent investigation before investing in any security after prudent consideration of all pertinent risks. Ahead of the Herd is not a registered broker, dealer, analyst, or advisor. We hold no investment licenses and may not sell, offer to sell, or offer to buy any security.

Richard owns shares of Evanesce.

Legal Notice / Disclaimer

Ahead of the Herd newsletter, aheadoftheherd.com, hereafter known as AOTH.Please read the entire Disclaimer carefully before you use this website or read the newsletter. If you do not agree to all the AOTH/Richard Mills Disclaimer, do not access/read this website/newsletter/article, or any of its pages. By reading/using this AOTH/Richard Mills website/newsletter/article, and whether you actually read this Disclaimer, you are deemed to have accepted it.