Graphite One CEO and President, Anthony Huston, Invited by President Biden to White House Investment and Job Creation Session; White House Sets 25% Tariff on Chinese Graphite

May 15, 2024

CEO to President Biden: “Projects like Graphite One’s are important in so many ways – from job creation and the renewable energy transition to technology development and national security.”

25% tariff on Chinese graphite set for 2026

White House meeting follows continued progress on Ohio advanced graphite materials production plant and Graphite One’s two Department of Defense grants

May 15, 2024 – Vancouver, British Columbia – Graphite One Inc. (GPH: TSX‐V; GPHOF: OTCQX) (“Graphite One”, “G1” or the “Company”), announces that CEO and President, Anthony Huston, was among a select group of company leaders invited by President Joseph R. Biden to a White House meeting focused on investment and job creation, including the strategic Critical Mineral sector. Hours before the White House event, President Biden signed an Executive Order establishing a 25% tariff on Chinese imports, including natural graphite.

The President spoke in the Rose Garden on Tuesday, May 14, 2024; a link to the public broadcast portion can be found here, and the White House tariff statement can be found here.

The White House tariff statement noted that “Concentration of critical minerals mining and refining capacity in China leaves our supply chains vulnerable and our national security and clean energy goals at risk.” Grouping graphite with the rare earths – both sectors dominated by China – the White House announced that “The tariff rate on natural graphite and permanent magnets will increase from zero to 25% in 2026.” The 25% tariff on Chinese synthetic graphite is currently under an exclusion that expires at the end of May.

“I was honored to represent everyone at Graphite One in the meeting with President Biden,” said Anthony Huston. “We appreciate his support for the renewable energy transition and G1 is excited to continue pushing forward to create a secure 100% U.S.-based supply chain for natural and synthentic graphite. The White House meeting underscores that projects like Graphite One’s are important in so many ways – from industrial investment and job creation to the renewable energy transition, technology development and national security.”

The White House event comes as Graphite One completed the initial planning sessions early this month at the Ohio site chosen for G1’s battery anode active material production plant, and continues to progress its two Department of Defense grant projects.

In Ohio, Graphite One senior management met with project consultants who are expected to assist with the designing and building of the synthetic graphite plant as well as with local companies that are expected to supply goods and services. Consistent with its commitment to hire from the local communities near the Graphite Creek deposit north of Nome, Alaska, G1 has made a formal commitment to prioritize hiring and workforce training in the Appalachia Ohio region in which G1’s advanced graphite materials manufacturing plant will be located, on the site of the former Defense Logistics Agency’s Warren Depot for strategic materials. As the core of G1’s commitment to community engagement, the Company is developing project labor agreements with local Ohio construction unions and has received letters of support from more than two dozen Ohio organizations including universities engaged in technology development, workforce traning, and projects to advance the build-out of renewable energy infrastructure in disadvantaged communities. The building of the plant and related employment opportunities remain subject to financing.

Progress on Graphite One DoD Grants

A week prior to Mr. Huston’s participation in the White House jobs and investment forum, Graphite One senior management took part in a Defense Logistics Agency (DLA) visit to G1 project partner Vorbeck Materials’ facilities in Maryland. The DLA site visit took place at the half-way point in the $4.7 million DLA-funded project to develop a graphite and graphene-based foam fire suppressant as an alternative to incumbent PFAS fire-suppressant materials, as required by U.S. law.

In its May 2024 project review session with the DoD project team overseeing Graphite One’s $37.5 million Defense Production Act Title III grant to accelerate completion of G1’s anticipated National Instrument 43-101 feasibility study (the “FS”), Graphite One senior management outlined actions related to the 2024 field season at the Graphite Creek deposit north of Nome, Alaska – the natural graphite link in G1’s complete U.S.-based supply chain strategy. Work remains on schedule to complete the FS as planned by December 2024 subject to financing. “As we near completion of the FS, we can now say that DoD’s support has cut about two years off of our initial Feasiblity Study timeline,” said Mr. Huston.

Graphite One’s Supply Chain Strategy

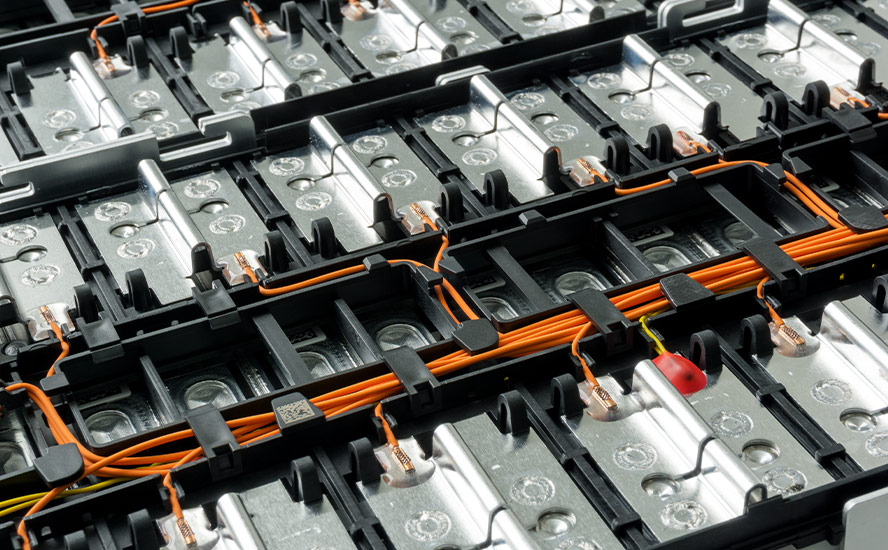

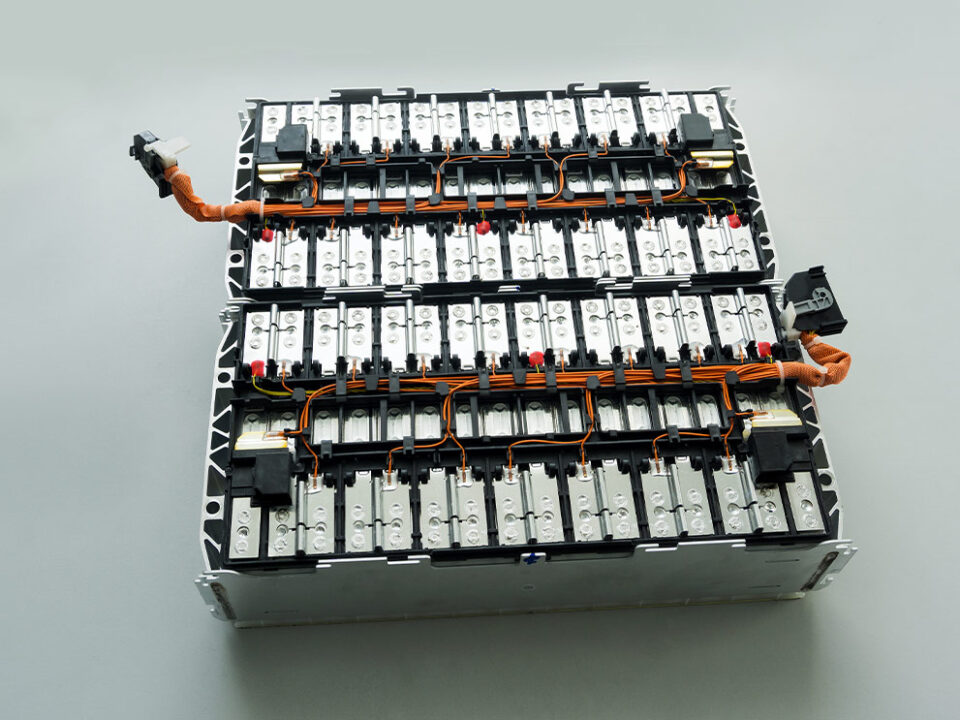

With the United States currently 100 percent import dependent for natural and synthetic graphite, Graphite One is developing a complete U.S.-based, advanced graphite supply chain solution anchored by the Graphite Creek deposit, recognized by the US Geological Survey as the largest graphite deposit in the U.S. “and among the largest in the world.” The Graphite One Project plan includes an advanced synthetic graphite material and battery anode material manufacturing plant located in Warren, Ohio. The plan also includes a recycling facility to reclaim graphite and the other battery materials, to be co-located at the Ohio site, the third link in Graphite One’s non-linear circular economy strategy.

About Graphite One Inc.

GRAPHITE ONE INC. continues to develop its Graphite One Project (the “Project”) to become an American producer of high-grade anode materials that is integrated with a domestic graphite resource. The Project is proposed as a vertically integrated enterprise to mine, process and manufacture anode active materials primarily for the lithium‐ion electric vehicle battery market. As set forth in the Company’s 2022 Pre-Feasibility Study, graphite mineralization mined from the Company’s Graphite Creek Property, situated on the Seward Peninsula about 60 kilometers north of Nome, Alaska, would be processed into concentrate at an adjacent processing plant. Natural and artificial graphite anode active materials and other value‐added graphite products would be manufactured from the concentrate and other materials at the Company’s proposed advanced graphite materials manufacturing facility located in northeastern Ohio. The Company intends to make a production decision on the Project upon the completion of a Feasibility Study.

On Behalf of the Board of Directors

“Anthony Huston” (signed)

Legal Notice / Disclaimer

Ahead of the Herd newsletter, aheadoftheherd.com, hereafter known as AOTH.Please read the entire Disclaimer carefully before you use this website or read the newsletter. If you do not agree to all the AOTH/Richard Mills Disclaimer, do not access/read this website/newsletter/article, or any of its pages. By reading/using this AOTH/Richard Mills website/newsletter/article, and whether you actually read this Disclaimer, you are deemed to have accepted it.